Monday morning bright and early, found me headed toward Brookville to shoot photos for the next edition of The Missing Conversation. Swinging past the shingle plant and seeing no rail activity or even any cars, I continued on south down Route 52.

My best-laid plans came to a screeching halt when I passed the northbound train just a few miles south of town. He was ambling along at a blistering ten miles an hour, which gave me plenty of time to turn around and scout ahead of him for a photo location. My choice wasn’t the best but knowing the area, it had to suffice.

Having gotten a so-so shot, I drove back to Brookville and parked near the Robert’s Mill site for another round of photos. Once he passed, I loaded up again and proceded back to the shingle plant, my objective having changed from a photo shoot of track details to watching him switch the yard.

With operations so sporadic on this line, watching them spot cars for the plant is something I’ve never witnessed. With the simple track arrangement, one could make educated guesses about the moves but first hand knowledge is always better than conjecture.

Arriving in the yard, the train pulls up shy of the fence around the plant and a crewman goes in to consult with the manager about what goes where. The work outlined, the Genset locomotive made his run-around of the cars and commenced sorting them into spot-order. With only a handful of cars, this didn’t take long. When ready, he made his shove into the plant moving very slowly. In fact, I was surprised at just how slow and deliberate this move was.

The engineer made his initial stop just shy of the fence that separates the plant trackage from the yard. The conductor is consulting with the plant manger about where to spot the inbound loads.

The train backs clear of the turnouts and the locomotive makes his run-around to the other end of the train because of the facing point siding configuration.

The cars are switched into spot order. With only a handful, this didn’t take long, but the moves were slow and deliberate nonetheless. A concession to the condition of the track here?

Shoving into the plant area was a slow deliberate process. I suspect tight clearances had something to do with the amount of care taken.

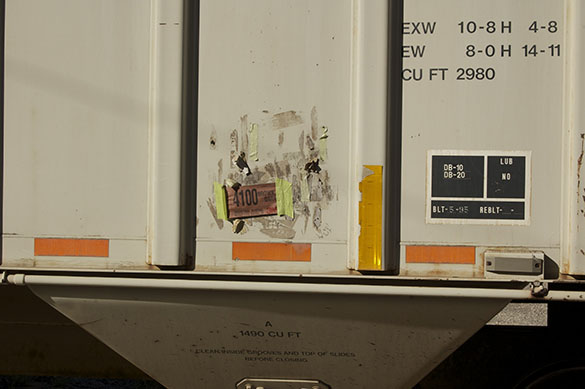

Once the inbound cars were positioned a plant worker came out and fired up the trackmobile for final spotting. At this point I headed out, but not before seeing another surprise. Each hopper had a tag on the side identifying the color of the aggregate. This has to make life easier for the trackmobile driver when shuffling things around.

This was my first encounter with a Genset locomotive and I was surprised at how quiet these things are. The is no revving sound as you expect with an internal combustion engine. When he moved there was just the constant whirring sound heard when idling. I had to move on due to time constraints but I have a clearer picture of the work at the plant and of the line as a total package. Every tidbit of knowledge helps.

Regards,

Mike

Sounds like a nice surprise. It’s nice to see a rail line come to life. Especially something that has sporadic traffic.

Greg

Magnificent. I hope you got all the details about the train Mike. Looks like you might have, considering your proximity to the action. Looking forward to reading your article about it in TMC.

Marz

Hi Mike,

Glad you caught the local industry job. It reminds me of some of the jobs I worked as a conductor. Most jobs I worked were at dark o’clock and not in such pleasant conditions.

I’d guess those cars were loaded with roofing granules from my neck of the woods hear in Wisconsin.

!!

Keep up the good work. I love the blog and the missing conversation. It just happened to coincide with a a my own interests as far as building more accurate track and scenery.

Ken Thompson

Hi Marz,

I didn’t cover it like I would have if I were thinking as a writer. I was definitely in rail fan mode and feeling good about watching them work the yard. One thing I noticed was that despite the simplicity of the track arrangement, there is more to the work than meets the eye.

After watching the operations at the plastics plant at home and the work outlined here, I’m more convinced than ever about the viability of smaller, simpler layouts.

Regards,

Mike

Hi Ken,

Good to hear form you and thanks for the kind words.

The majority of inbound cars are Wisconsin Central two bay covered hoppers. I’ve also been surprised to see three and four bay “grain” hoppers too. I would have thought the granules were heavier than grain but maybe they are similar in both weight and density? I don’t know.

Regards,

Mike

Too true Mike,

I think at the heart of it, we are all rail fans first. The simplicity is exactly the key to what we as modellers are trying to achieve. The prototype does not create switching puzzles to give the crew something to do! That’s why I asked if the operation was documented, it would make for an interesting read and enlighting the knowledge bank.

Small, simpler layouts can be just as rewarding, if not more so than basement size empires. I just comes down to personal choice. I am definetly in the former camp.

Nice photos by the way, keep up the good work.

Marz

Mike, Wonderful study and observation of local/regional economy, railroad ops and catching it when you can. This is the lifetime stuff that has always fascinated me regardless of our numerous residences. Same here at the retirement locale: local Md and Del RR short line this week started it’s seasonal (record) grain corn and soybean harvest on the two branches. 41 empty hoppers have been stored at the end of the main, just like your previous TMC pic of parked cars…why are they there? Movements from that storage to the grain epicenters, clogging the mains and requiring coordination with other end-of-line industry movements, Facebook heads-up from the conductor re working schedule of these industries; the dance, hustle, and waltz of commodity interchange congestion with NS. I love this time of year and can, and will, be modeled…talk about a hectic operation. It’s stuff like this that leads me to wander aimlessly through train shows that, regardless of scale, seem primarily oriented toward train “runners” and accumulators vs actual “modelling railroads”…aimed at a community that does not, at its core, understand how a prototypical railroad operates.

Thanks Pat.

I remember a couple of record harvests from childhood. The PRR stuffed boxcars into every siding in town. I counted 17 forty-footers on the siding next to the house. Of course, they had to be moved in order to work the industry and then put back.

Another year, there was so much corn, the elevator couldn’t hold it all. They blocked off a side street, put down plastic sheeting and snow fencing and just piled it on the ground for half a block at a depth of at least four feet. Day and night, the roar of the grain dryer didn’t stop for weeks.

Mike