Methods OF Work-2: Dealing With Crude Details

Your Mindset Is A Tool

When I sit down at the bench, I’m aware of how easily I can ruin days, weeks, even months of work in about two seconds or less by being careless. A moment of inattention and a slip of the tool can ruin your day quickly.

I believe our mindset is a tool that’s as important as any other on the bench. I believe it influences not only how we approach the work, but the results we see. I’m impatient and tend to rush things. One of the first things I do before getting to work is to slow down. I’ll start a CD of favorite music or just sit for a moment to review what I did in the previous session and what I want to do next. It’s only a minute of time spent but this routine helps me settle down and focus on what I want.

Once settled I can dive in and work without interruption. The music acts as white noise that eliminates distractions. When I feel the urge to rush the work, I have to make a deliberate effort to slow down again. Sometimes I just need a break to get up and stretch or maybe grab a snack. The lesson I’ve learned is how to recognize this behavior and its effects on my modeling. By taking simple steps as needed my work and enjoyment of the craft has improved.

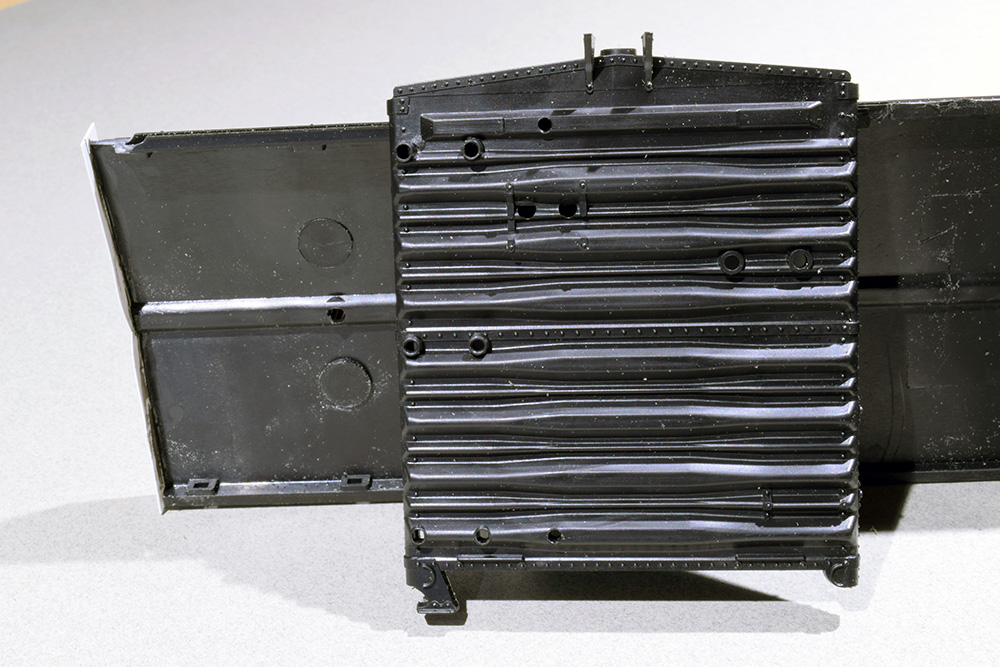

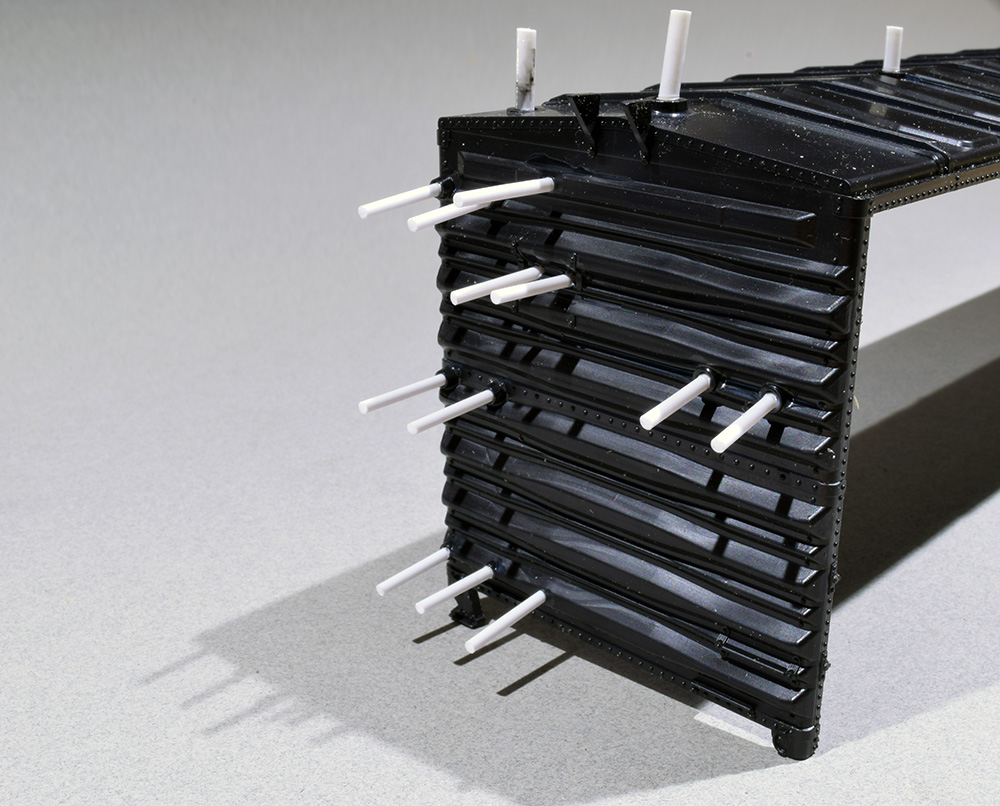

I plugged these oversized holes with styrene rod and let the glue harden overnight. The car end looks like a giant pin cushion at this stage.

What Am I Trying to Do Here?

I want to improve my modeling and take the time to evaluate the work I’m doing. Beyond the obvious of building a model, there are several things I may focus on during a work session such as:

Am I working to the standard I want?

Am I improving my technique or phoning it in just to move a project along?

What can I do better than last time?

We tend to make vague statements to the effect that one day I’ll get better, without actually defining what “better” is. Being specific leads to real improvement as you have an objective roadmap to follow.

Giving Up Without Trying?

Unfortunately, the general hobby doesn’t encourage this approach, which leaves modelers on their own to deal with the questions that need to be answered. We’ve all read or even uttered the comment of “Gee, that’s nice but way too hard for me.” Really? How do you know? Have you tried it? “Uh, well…”

I’m as guilty as the next guy. I’m drawn to the most amazing work but seldom put in the practice time to get to that level. Why? Because I don’t want to admit to myself that I’m not as skilled as I like to think I am. That’s my ego talking and it isn’t helpful. The simple truth is that I have a lot to learn and I’ve started late in the game.

We hear about practicing a technique to get better but few understand that improving any skill is a long term process and people want everything now. We seldom hear about how to learn and get comfortable with failure (a lot of failure) before the quality comes. But, that’s the nature of any type of creative work, including model making.

Shaping the plugs to match the profile of the ribs requires a light touch with a sharp blade. Brute force isn’t needed here but control and patience are. I only used the knife to waste away the bulk of material, then switched to small files, sanding sticks and sandpaper to shape the plugs. This is a skill you only learn by doing it. Yes, I made mistakes but that’s what modelers’ putty is for.

Everyone Has Their Own Way

A comment I often get is about a faster way to do a task or how I should use this or that tool. I appreciate the insights, as they are useful. I want to add however, that we all have different temperaments and preferred ways of working. While there are many ways to fill and shape the plugs on the model, I like the process of carving and shaping the details by hand as shown in the photos. Others will prefer a different way. We can all agree, there are lots of ways to get the job done.

I’m not offering a prescription or recipe for successful modeling. I’m just sharing things I deal with or consider in my work in the hope that someone else may benefit.

Regards,

Mike

“This is a skill you only learn by doing”

Hear, hear.

–Simon

Mike,

I hope you didn’t take my comments last week as insults to your modeling.

I too put on background noise (podcasts) while I work.

I think the hardest part of kit bashing/scratch building is just starting.

Craig

No, not at all Craig. I appreciate your input and comments on the blog. I simply wanted to make the point that we all have favored methods of working. I’d love to tool up with a lathe, a mill and other advanced tools, I just can’t swing the cost right now. Rather than wait till “someday,” I keep the modeling moving forward with the resources I do have.

Mike

Mike,

I understand now. I too would love to have a large and milling machine (and the skills to use it).

We adapt to what tools we are most familiar and comfortable with. I for one have been turning to 3D printing for detail parts. Its “easier” for me to draw up the design and orde the print than to scratch build some parts.

Craig

Suggestions about a faster way to do something: This is a hobby, not a race track. You get faster by learning, you learn by doing. Is the key to happiness found in getting faster? Maybe if you’ve got a basement to fill with track and cars, but then what level of modeling are you doing anyway? You’re always working fast enough if you’re accomplishing your goals. Doing and improving are key. As long as you’re moving forward and your goal isn’t so big it’s permanently out of reach, who really cares how fast you work as long as you’re doing something?

To me the suggestions should be on how, not how fast. “I know a technique that makes that easier.” “There’s a shortcut that improves what you’re trying.” “Are you interested in another approach?” That’s far more productive as input that helps you grow as a modeler.

I completely agree Dave.

Cheers,

Mike