I’ve been watching a video series produced by Brian Banna of his Precision National GP38M build. If you’re interested, there’s a link to the series at the end of this post.

I’m a visual learner and when I can see how a procedure is done, my understanding is greater than it would be from just reading a text and looking at still photos. In watching Brian work, I can see how to hold a tool, what kind of hand motions are required and how much force is needed to do the job at hand. Brian puts a lot of thought and effort into his videos and the quality comes through, even though YouTube did something funky to his earlier videos. That said, the camera work and narration in his recent series is excellent and it’s easy to see the processes involved and follow along. All of this is my long-winded way of saying I’m learning a lot from this series.

I’ve made progress on the ACF boxcar build and have moved on to the side panels of the car. The welded sides should have been a straightforward build but I’ve redone them three times and I’m seriously considering doing them a fourth time.

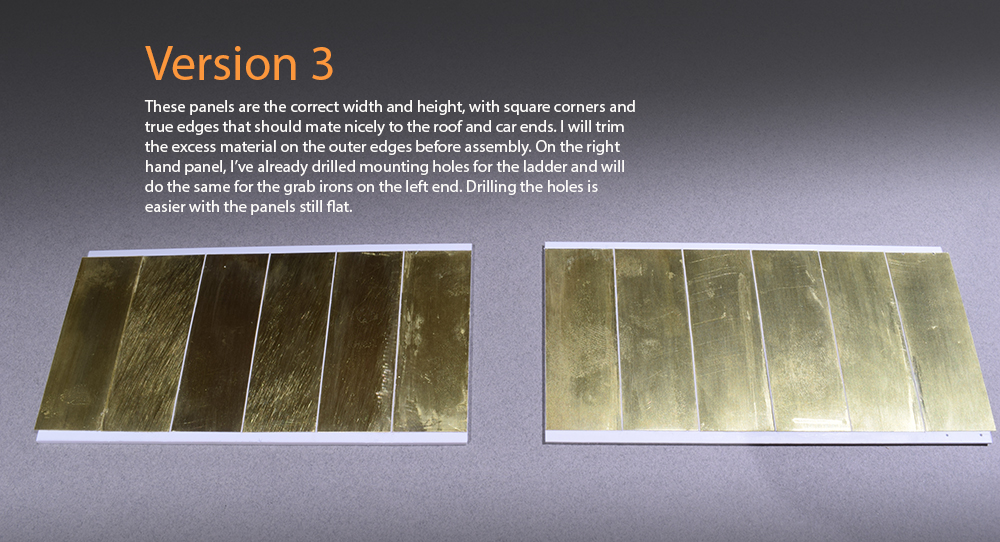

On the first two attempts I cut the side panels to the wrong dimensions in both the height and width. Both errors could have been corrected with filler strips and I nearly went that route. However, I want to improve my work and technique and that starts with my mindset, so I remade the four panels for a third time, taking extra care in measuring and layout.

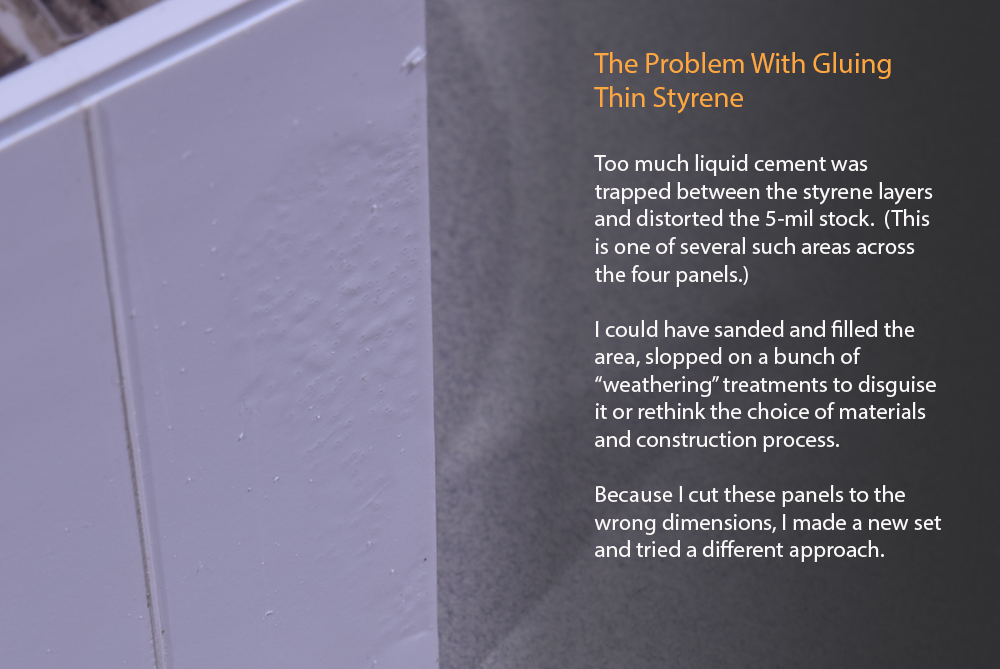

Beyond the dimensional errors, the construction materials and method I chose wasn’t the best for the job. I made each panel with a sub-base of 80-mil styrene, which was fine. The issue came from laminating pieces of 0.005″ stock to this sub-base. Such thin material distorts easily if too much solvent is used and these pieces warped and blistered in several places as you can see in the photo below.

It wasn’t a total disaster and I could have lived with it but chose to remake the sides a third time and correct the errors that were piling up. For the third set I switched from styrene to 0.005″ brass sheet. I used this combo on the PS5344 build and liked the result. As with the styrene versions I cut the brass into 3′-5” wide strips for the individual side panels and used 10-mil styrene rod for the weld beads.

Everything was going nicely until I ran out of styrene rod with just one weld bead left to finish. I found a package of 0.010″ brass wire in the drawer and completed the panel.

Having reached the fairy tale ending, I should wrap up this post, except I haven’t explained why I’m considering redoing the car sides for a fourth time.

The next day it occurred to me that 10-mil styrene rod might not be the best choice for the weld beads. It is fragile stuff and may not stand up over time even with careful handling of the model. A second thought was that I might have made a mistake in laying out the six individual panels on each quadrant of the car side. It’s only a fraction of a scale inch but the error accumulates. The question to answer is it worth the extra work and material to fix?

My answer is yes, if doing it right enhances my enjoyment of the work, which it does. I can live with slight errors of a scale inch or two. I strive to get things spot on but my skills aren’t there yet and I accept the learning process for what it is: a process of making mistakes and learning from them.

As for the plastic weld beads, I have options. I can wait and see how they hold up. I can remove them (I have a nice reject pile to practice on) and replace them with more brass wire, or if that doesn’t work, then I can rebuild the panels again and apply the lessons learned.

Why go to this much trouble? For one reason: I’m tired of just phoning it in with my modeling. From watching Brian’s videos I get to see what craftsmanship looks like in practice and that has changed how I approach my own work. I’m able to see the path forward to better modeling and I see the difference that taking your time and exercising care makes. I enjoy where that path is taking me. I hasten to add that I’m not offering a prescription or methodology for scratchbuilding. I’ll leave that to the self-proclaimed experts. I’m also not seeking advice on how to do things. I’m simply sharing my learning curve and experience in modeling. Take what you want, have a good laugh at my expense or ignore it altogether. I’m enjoying myself and that’s all that matters.

Mike

0 Comments