Patience and determination pay handsome dividends in modeling. These qualities are grown over time by dealing with mistakes and by having a set of personal modeling standards. One modeler who epitomizes this is Tony Sissons. Tony’s work is well known on the Railroad Prototype Modelers’ circuit and is the subject of a new title from OST Publications that’s coming later this year.

For this work, Tony describes the process for breathing new life into an Athearn SW1500 dummy unit he found at a flea market. As with much of Tony’s work, he went above and beyond simple upgrades and created a fine model by redoing the radiator and fan in addition to other modifications and adding a motor and drive train.

The safety grill over the radiator on an SW1500 is a highly visible detail. Tony went the extra mile by etching a finer profiled safety grill to replace the commercial grill, which he felt looked a bit coarse. The process of scratchbuilding this detail is where patience and determination make the difference between good enough and excellent. Here’s part of his description:

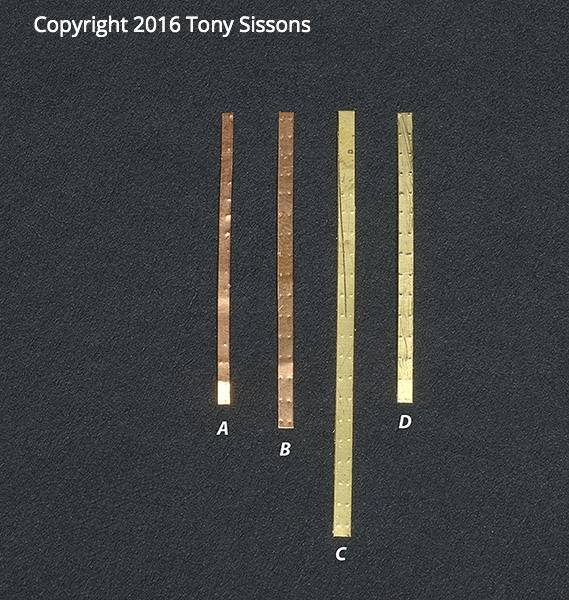

“I found building this to be annoying rather than difficult. Keeping the bolt impressions equally spaced and in alignment was a pain. The photo shows the four stabs I had at it. For piece A I used a pounce wheel for impressing each bolt head and immediately dropped that idea. Piece B turned out pretty well with the only thing I didn’t like being the soft copper material doesn’t leave a crisp bolt head, so I opted for brass. Piece C came out as good as I was going to get, other than when I made the cut to separate the strip from the large piece of sheet brass. The knife blade drifted toward the center of the strip, as is plain to see. My fault of course so that got scrapped too.

Finally piece D, which has an odd imperfection, but once fitted with the grill section then painted and lightly weathered, I was certain that any imperfections would be hidden to the naked eye. When I positioned the etched safety grill again I was disappointed, dissatisfied even, that the single section grill was not per the prototype. So at the end of the day I decided to separate the grill etch down the center and space each half along the centerline and adjust the radiator a little to match the shell.”

It’s true that not everyone will go to this trouble or have the skills required to do their own etches like Tony. Yet, one of the lessons his work teaches is that by acquiring such skills, he is free to carry his modeling to whatever degree of finish suits him. He isn’t bound by the quality of commercial products or their availability. He can set his own standards for the work and this gives him a tremendous freedom and sense of satisfaction. Tony has been modeling at a high level for many years, yet he started out like all of us, making plenty of mistakes along the way. He is a relentless critic of his own work, but always generous with encouragement and praise for others as they travel their own modeling path. I think you’ll enjoy the book.

Look for more specific details on this book project in the near future.

Regards,

Mike

Someone wise told me recently that they make most parts twice — first to figure out how to make it, and the second time to actually make it. I’ve been repeating it so much, I’ve forgotten who said this in the first place! In my case, twice is a minimum, and often like Tony, I make things three or four times before I get it right.

If more new modellers knew this, they would be less frustrated by their lack of skills. The fine models that we see through OST and other publications are not knocked out of the park on the first pitch!

That is so true Rene’. My first build of the boxcar was a giant experiment to see what would work and what was impractical. The second build was a culmination of what I learned.

So good to hear from you again. I’m following your progress with the 622 with interest. CAD work is quite alien to me.

Regards,

Mike