I made a promise to myself.

I need to move the PS 5344 project along for Part Two of the Scratchbuilding theme that’s coming in Volume 12 of TMC. So, with the bone cold atmosphere in the basement, I fired up the space heater and pulled it as close to the workbench as the cord allowed.

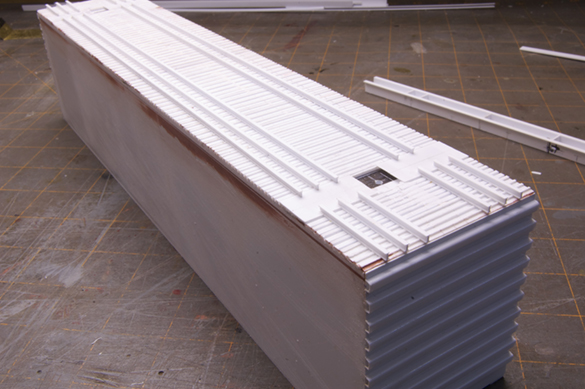

Progress was made as I passed two hurdles that intimidated me due to failures in the past. I’m pleased to say the soap opera of the corrugated end panels is finally over. As I shared in Vol. 11 of TMC, I discovered corrugated sheet material from JTT that had the right rib profile but wrong spacing. Cutting the individual ribs from the sheet solved the spacing issue and the end result is satisfactory. Sticking to my vision of what these ends should look like and not compromising just to make progress leaves me with a good feeling. It was worth all the trouble, failed attempts and blind alleys traversed in search of a solution.

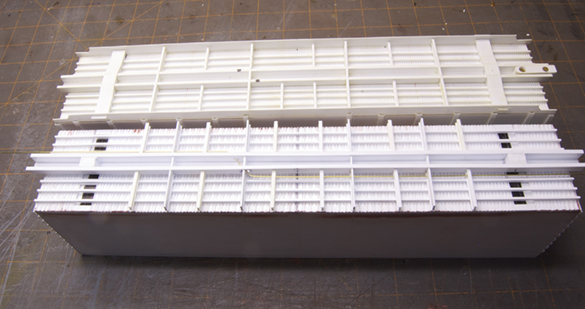

The second hurdle involved the underframe. Again, Vol. 11 told the tale of missed opportunities that plagued the first build. Since then I have obtained better reference photos of the full-size underframe that revealed other errors I didn’t even know I had made.

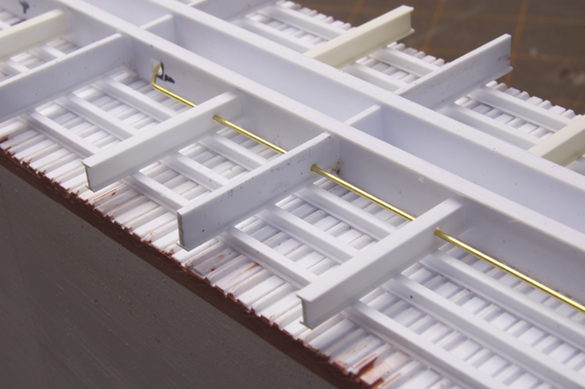

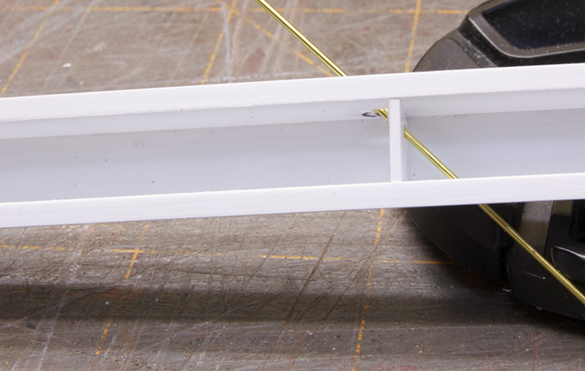

My work centered on drilling the holes in the cross bearers and I beam floor supports for the train line. These holes had to line up and creating such precision has never been a model building strength of mine. I followed my own advice for once and took the time to think through the steps involved and the order in which they had to happen. I also had to consider the adjustments needed for the different sized components. In the end, everything lined up, thanks to the use of a drilling jig to locate the hole in each member. Threading the 0.032″ brass wire for the train line and watching it ease through the holes was enjoyable.

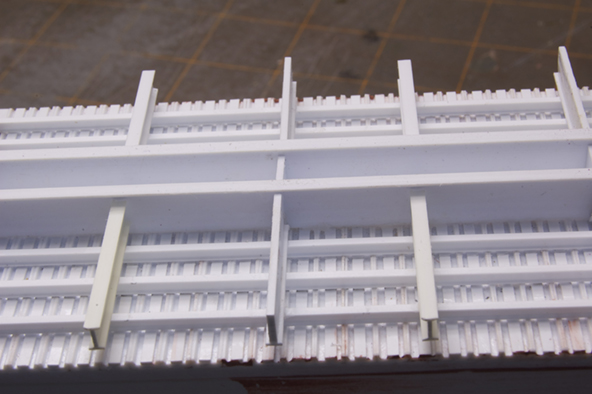

The first order of business on Monday was to strip it, all of it, off and start over.

Some of you will understand (thanks for the email Bill), others will wonder why on earth would I do that? Because I hated it. I don’t know if it was my rush to get out of the cold or my jitters but the end result wasn’t up to the standards I set for this project. A close, critical examination revealed more sloppy workmanship than I care to admit and experience has taught that such lax work would haunt me for the rest of the project. The time to fix it is now and, that’s what I did.

We tell ourselves stories.

We tell ourselves stories about this craft that simply aren’t true. The common story here goes: “Who cares? No one will ever see this stuff and besides, it looks good enough to me. Paint and weathering will cover up the mistakes and no one will ever know.”

I’ll know.

For as long as I’ve been modeling, I’ve told myself the story that serious work is beyond my skill set. I’ve accepted a mental image that focuses on reaching a predictable level of workmanship and then quitting, because I think I’ve done my best. It’s a lazy, complacent attitude and my work on this underframe is another chapter in that tiresome narrative. It’s time to throw that book away and start writing a new one.

What you see in these final two photos is the beginning of the second underframe on the second build of just one car. I learned from the previous mistakes and avoided them while building the second center sill. As long as I’m learning and growing, none of this is a waste of time. This is what scratchbuilding really looks like. It has little or nothing to do with: “Cut Part A to length and glue it to Part B using CA.” It has everything to do with asking questions, making critical judgements and learning from both. I will keep going if it takes a third, fourth, fifth or even a sixth attempt to get it right. I will keep going, even if it takes another five years beyond the five plus years I already have in this on again-off again project. Why? Because I made a promise to myself. A promise I intend to keep.

If you haven’t already, grab your copy of The Missing Conversation, Volume 11 here. And please accept my heartfelt appreciation and thanks if you do.

Regards,

Mike

“I’ll know.”

Best motivator for going the final mile I know of.

Nice post.

Simon

Mike,

Your story sounds exactly like my scratch building trial. I thought I was the only one worrying about 0.010″ of an error. I’m not sure if you motivated me to throw away what I’ve already started for the 3rd time, or made me realize all of the mistakes that I’ve already have tried to cover up. I’m getting motivation following your successes and failures in 1:48. If you can make it perfect in 1:48 I sure that I can do it perfect in 1:29!

My build is more of a prototype for a brass model (even more skills to learn) but now I’m tempted to start over from the beginning.

Craig

Hi Craig,

I’ve developed a simple guideline. If I can look at a detail and walk away without thinking about it again, I’ll leave it alone. If I start feeling regrets as I’m working or do nothing but think about it over night, I’ll redo it. This seems to work well for me.

Regards,

Mike