Much of the layout design literature is geared toward HO and N scales. In my view, this creates problems for those of us working in larger scales like S or quarter-inch. There is an unspoken belief that the same rules are applicable to any scale. My own experience suggests otherwise.

In this post, I’m thinking of the basement filling, operations oriented HO layouts that most consider the ultimate expression of the hobby. While this type of layout is certainly possible in quarter-inch scale, it comes with its own set of costs and trade-offs.

I’ve worked in both scales and there are few if any similarities between them. Quarter-inch is a different ballgame. I have never used S or N scales, so I’m not familiar with them. I’m hoping readers who work in those scales will weigh in on this post, or perhaps share their experiences on their own blog and link back here. (Hint.)

Beyond the folklore of dealing with impossibly large curves and big turnouts, layout design in quarter-inch has non-obvious factors that impact any layout. Here are two from the short list: Train length and Surrounding Spaces

Train length

Recent years have seen a trend toward running longer trains. Train length is something most of us don’t even think about but it quickly becomes an issue in this scale. I mentioned in a recent post that a typical forty-foot boxcar in 1:48 is ten inches long and, you’ll add another quarter to half an inch when you measure from the pulling face of each coupler. (It should be noted that the space between cars adds up quickly.) Fifty and sixty-foot freight cars are over 12 inches, while that 80 foot Pullman car can exceed 20 inches. These specs are just for the cars, we haven’t added a locomotive or caboose yet.

With cars this long the problem becomes obvious. A train of 20-30 cars plus engine(s) eats up a lot of wall space before it even goes anywhere. I have watched such trains in action and they are an impressive sight, however, they need room to look right. On my old layout, such a train would have stretched from one end to the other with nowhere to go.

Assuming a single track mainline, long trains need long sidings to get around each other. In quarter-inch scale siding lengths for mainline freight trains can stretch twenty to thirty feet or more in length. A related issue involves the turnouts at each end of any passing siding. I used No. 10s and they require four feet from the tip of the switchpoint to reach the clearance point where two cars can safely pass each other on the adjacent track. This also needs to be factored into any planning.

While number 10 turnouts seem extravagant, in my experience using a shorter turnout is a false economy. You really don’t gain anything and they come with a substantial cost to the appearance of the train going over it. You’ll have to decide which is more important to you.

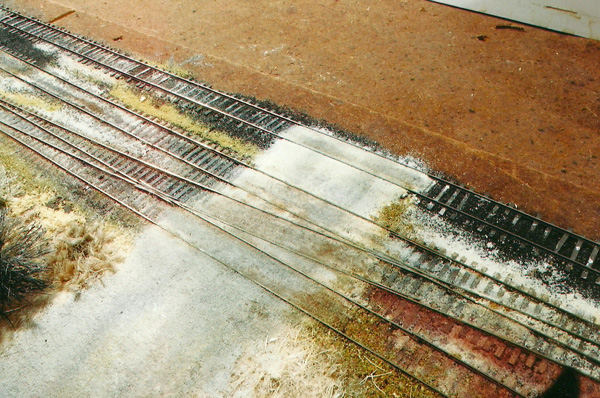

While it isn’t apparent in this view, it takes four feet to reach the clearance point from the toe of the switch points of this No. 10 turnout.

On most HO layouts, one is lucky to have 20-30 feet of track between sidings. Many won’t even come close to that much space between towns. In 1:48 the issue is even more frustrating. Consider this: if you only have one hundred feet of mainline, that 20 car train is going to travel just five times its own length. That’s hardly the cross-country distances we picture in our imaginations. The age-old solution in this scale is to loop a double track mainline around the room as many times as feasible, which leads to overcrowding, and leaves little room for anything else like, scenery, for instance.

The issues around train and mainline length aside, let’s talk about the support areas like yards and engine terminals.

Even a modest branchline terminal with a 60-65 foot long turntable and three-stall roundhouse will eat up the area of a 4×8 sheet of plywood. A six-track freight yard can require benchwork between three and four feet deep. How will you work the rear tracks or read car numbers that far away? It’s something to think about before the track goes down, not after.

With a benchwork height of 54 inches, reaching in to uncouple cars wasn’t an issue unless there were cars sitting on the front track of the yard. If so I couldn’t see the car numbers or reach the couplers. It’s a case of not thinking things through.

Surrounding spaces

Given how the track eats space so quickly, there is little room left for scenery. Layout builders tend to stuff things into whatever spaces are available, with the resulting crimes against realism.

Structures in this scale, even small ones, leave big footprints. For example, I have a model of a small town depot that measures 7.5 x 14.5 inches. On the typical two-foot wide shelf with one or two tracks running down the middle, this building would be jammed tight against the backdrop. How will Aunt Millie and Uncle Ed pick up the stuff they ordered from the Sears catalog? There’s no room for the scene to breathe, which leads to an overcrowded toy-like appearance. Many widen the benchwork to 30-36 inches and while the extra width helps with scenery, it adds to the cost of material and may create reach-in issues or create a choke point with the aisle. It’s a trade-off born from not thinking of the design as a whole.

Another common situation on layouts in this scale is miles of retaining walls, rock cliffs or fill with slopes that would never be stable in real life. Once again too much track in too little space is the root cause. Historically, layout builders just accepted these situations as the price to pay for the amount of running they want.

Three tracks in HO

Same number of tracks and same bench work width in quarter-inch scale. As you can see there is a lot less room for scenery or structures.

And The Magic Formula Is?

This is the point where most articles trot out the author’s pet formula or ten step rules for achieving the perfect layout. If you’ve read more than two posts on this blog, you know I don’t believe in such rules and formulas. Instead I’ve spent the last seven years dissecting them and encouraging you to do the same.

People come to this craft with vastly different wants and desires, yet we hand them a formulaic cookie-cutter approach. The layout design literature assumes everyone works in the same scale and promotes a design language that is assumed to work for every situation. It doesn’t. I’ve discovered in ten years of working with quarter-inch scale that treating it like HO on steroids is a mistake.

If there is any secret at all to layout design, in my view it starts with the modeler, not a list of gotta haves or givens and druthers. Regardless of the modeling scale, it begins with knowing what’s important to you and what isn’t and having the strength to ignore the stuff that isn’t. I believe the ability to make a clear choice is a subject we don’t give nearly enough coverage to. The mentality that you can have it all and that you need it all is well entrenched.

Layout design is too personal and reducing it to a set of rules or cookie-cutter solutions diminishes it further. I’m a rank beginner by the standards of this scale and I don’t have a set of Mike’s Golden Rules For Working In Quarter-inch Scale. What I do have however, is a bit of perspective based on experience and that’s all I’m offering here. Decide what you actually want, give the scale its due and things will be fine.

Mike

Once you pass HO in size, you must model different: a Branch with short trains of a few cars, not the Main; or an Industrial Park with its switching. Unless you happen to own a barn or a former manufacturing facility.

I’ll modeling indoors in Large Scale. It is a depiction of a small town on a Branch with only three customers…and will fill half a Basement.

Hi David,

I appreciate you taking the time to write in however, I disagree with such broad generalizations. I know people in this scale that model mainline operations in modest sized basements. They don’t have room for multiple town sites but do each scene well rather than crowd things. I do agree that in this scale to have multiple towns with lots of space in between takes more room and resources than many have or are willing to give. Regardless of the scale or subject matter, the key, in my view, is to understand the subject and to know what you want from it in terms of personal satisfaction. Your own efforts sound like an example of doing just that.

Mike

Four Feet for a #10…wow, that really drives it home.

Two thoughts – John Armstrong’s Canadaigua Southern and of course, Frank Ellison’s Delta Lines. That’s what comes to mind when I think O scale railroad planning. Both seem like exercises in cramming as much railroad into the space as possible, each using tricks and gimmicks to either compress space or time or both.

But in each case I think the layouts built were representations of what was important to each builder. As I read Ellison on operations and the drama of railroading, I get a sense of the excitement he probably felt as he and his operating crew moved trains over the line from Fillmore past each little burg along the way, picking up and setting out, avoiding the fast passenger trains, etc.

I hear you wrestling with issues of replicating reality in a more genuine way, with fewer gimmicks and less-obvious compromises.

On a slightly different tack, let me refer you to a beautiful British O sectional exhibition railroad, Newchapel Junction. There are several videos of it in operation on YouTube and a website documenting construction. This railroad seems to focus on moving trains in and out of a large station and, depending on the site and setup, down a branch to a small terminus. Functioning signals seem to be a prominent feature. I mention it because it is an example of a builder who clearly has a well-defined set of goals and expectations for his railroad and has found a way to execute them to a high degree of quality.

The late Donald Boreham once advocated that the best scale to work in was the largest one that would fit in the available space! OK he was a narrow gauge modeller, but the statement is not as trite as it seems. In fact it is incredibly subtle and powerful.

It actually reframes the question into two questions:

1) What is it that I want to model? (From heavy operations down to individual models, such as your recent cameo, to just individual models without even a setting – maybe even large scale live steam.)

2) What resources do I have? (Space, time and money. Skill is acquired through determined practice – it does require time and determination to build, but is not a resource in and of itself.)

The more one leans towards operation of a system, the more a smaller scale like H0 or N makes sense. The more one leans towards construction and maybe limited operation – running the daily mixed train, perhaps – then larger scales make more sense, but in a limited space, then even a layout may be out of the question.

Personally, I find there is a balance between the extra mass gained from a larger scale and the ability to accommodate a layout in a U.K. garage within S scale, having grown up with 00 and dabbled with 0 and 1 gauges. The size of the Models appeals to me, and has done since I first saw it at the age of 13 or 14.

The “problem” for most modellers is that they haven’t really worked out what they actually want to model…

And of course, both resources and inspiration can change and evolve over time.

Simon, possibly not being directly helpful, but posing questions rather than providing answers!

I agree Galen. I agree that both layouts satisfied their owners desires but also, that both were very much products of the times and technology available then. Both men pushed the ideas beyond the conventions of their day. Both men also brought all of themselves to the work, Ellison as a theater designer and Armstrong’s relentless curiosity and tinkering.

I think this is important. So many expect a formula, a layout or some gadget to provide satisfaction with the hobby but, any such satisfaction will be short-lived before it’s on to the next flavor of the month. I want to bring all my interests to the work and find there is a place for each of them. I’m more convinced than ever that the hobby consists of the ideas you bring and the willingness to explore different directions with it.

Mike

Mike

Well said. As always.

Mike