Truthfully, this is where I want to be going forward with modeling. There’s a mix of intimidation, eagerness and anticipation to each step. I feel engaged with the work in a way I’ve missed in recent years.

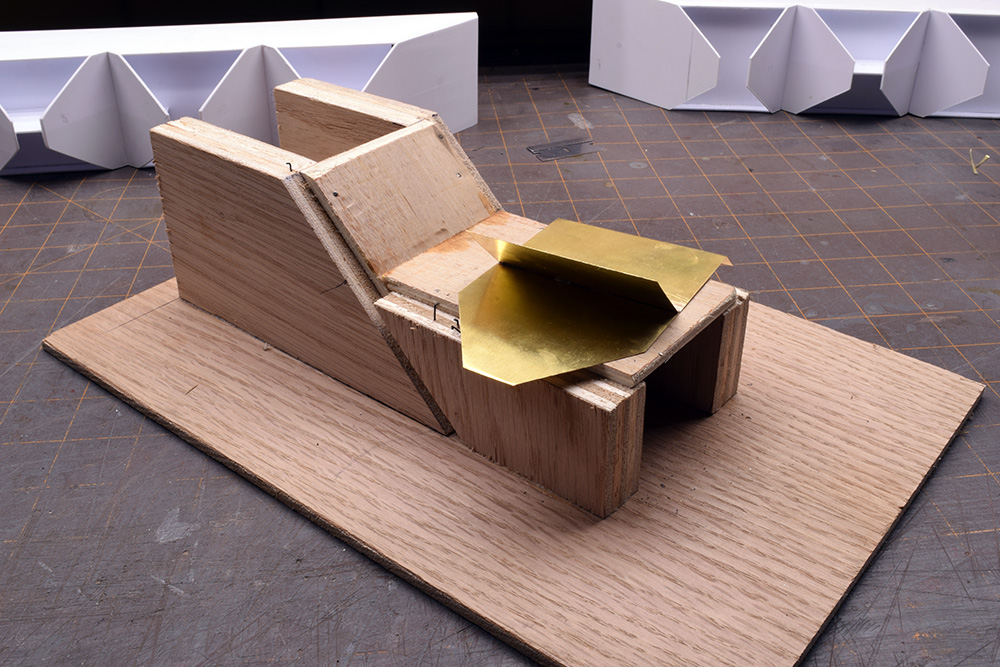

I’m treating this project as a series of challenges and questions. The first phase was to build three substructures to the same specs and understand how that process works. While they aren’t machine perfect, they are very close. I learned how quickly I make assumptions that aren’t based on the prototype and also the value of tools and systems that ensure repeatability and accuracy.

(Photo above) The slope sheet seen here is not the finished piece. The vertical sheet needs to line up with the center of the truck bolster, and there’s no room for error. The piece shown is a little off in both size and position, so I have more work to do. I’m also not entirely happy with the solder joint and I’m looking at other methods to see if I can get a better result.

Instead of questioning the necessity of a compromise, we blindly accept it. Some of them are unavoidable due to manufacturing, material limitations or modeling scale, while others still linger because of tradition and the status quo. Examples of the latter include coupler box openings the size of Montana or excessive truck swing arcs. Both are holdovers from toy trains rather than scale modeling.

The more I work with P48, the more irrelevant I find many of the hobby’s so-called truisms. Things like the three-foot rule and others that are largely based on HO have proven to be of little consequence to my quarter-inch scale modeling. With the larger models and close-up viewpoint, the amount and quality of individual details creates a greater impact than anything in HO or N scales; so why be a slave to the mindset and standards of a scale that don’t actually apply to what I’m doing?

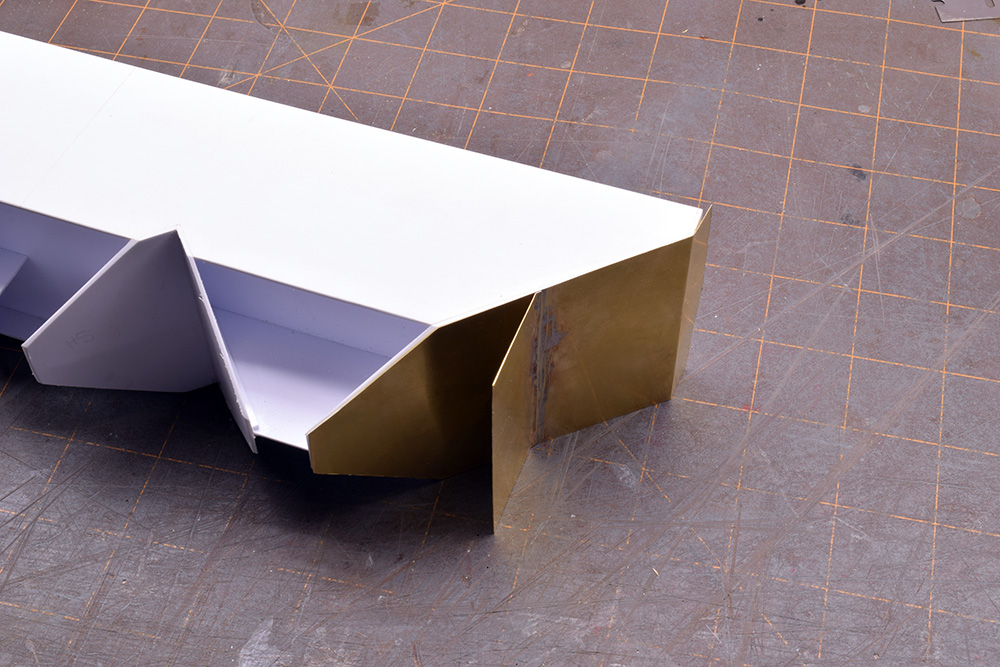

(Photo above) Making the brackets from 0.005″ brass was a straightforward and relatively simple task. I did enough for all three cars in about two hours.

For my work, good enough is a moving target that shifts as my skills and knowledge evolves. Quality that was acceptable a few years ago isn’t anymore because my skills have improved and I expect more from the work.

To be certain, not everyone enjoys model building. For many, the outcome isn’t worth the effort involved. But building things is a fundamental part of the craft and instead of making everything as easy as possible, I believe that satisfaction comes from meeting new challenges. I believe that the more options I give myself in terms of skill and knowledge, the greater my enjoyment of the craft will be. I believe there is always something to learn and be curious about. As I said earlier, this is where I want to be with the craft.

Mike

“This is where I want to be with the craft.”

At the frontier.

Not THE frontier, where you are pioneering brand new techniques (if it happens, though, please share!), just the frontier of your own comfort zone.

Good place to be.

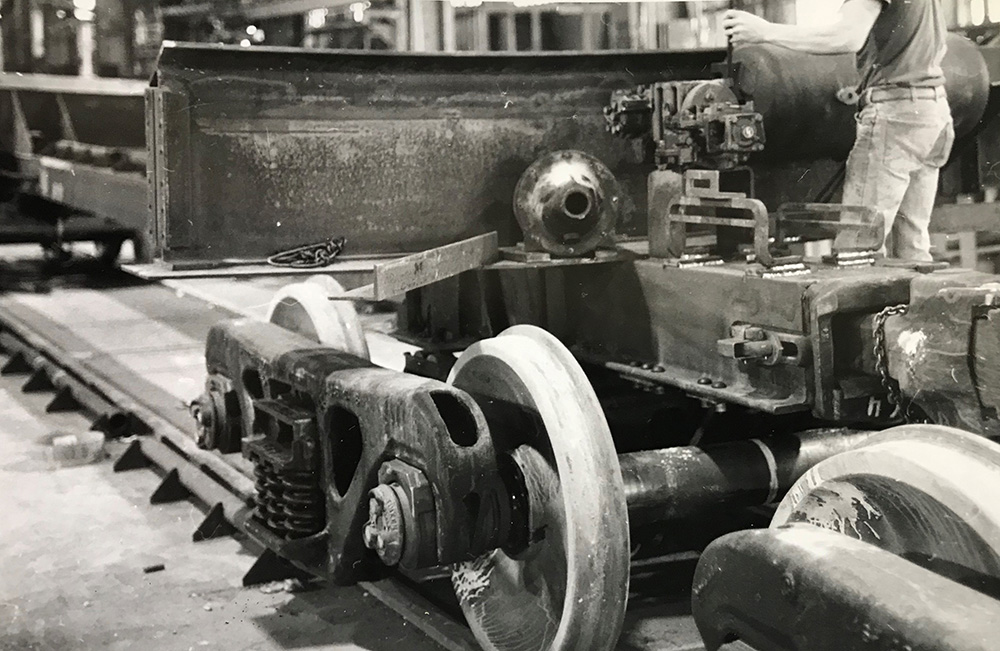

Great progress again Mike. When I stumbled on to those photos I thought it was interesting how what there shop is building and the progress is very much like your starting point on the model just a bigger size.

Your brass work is very nice so far. Little bits like your air tank brackets will be what all adds up to a tremendous model. A pain for sure and worth it in the end.

Thanks guys.

Simon: It is a good place to be. I’m enjoying this build immensely.

Steve: I appreciate you and your dad sharing the photos and letting me post them here.

Mike