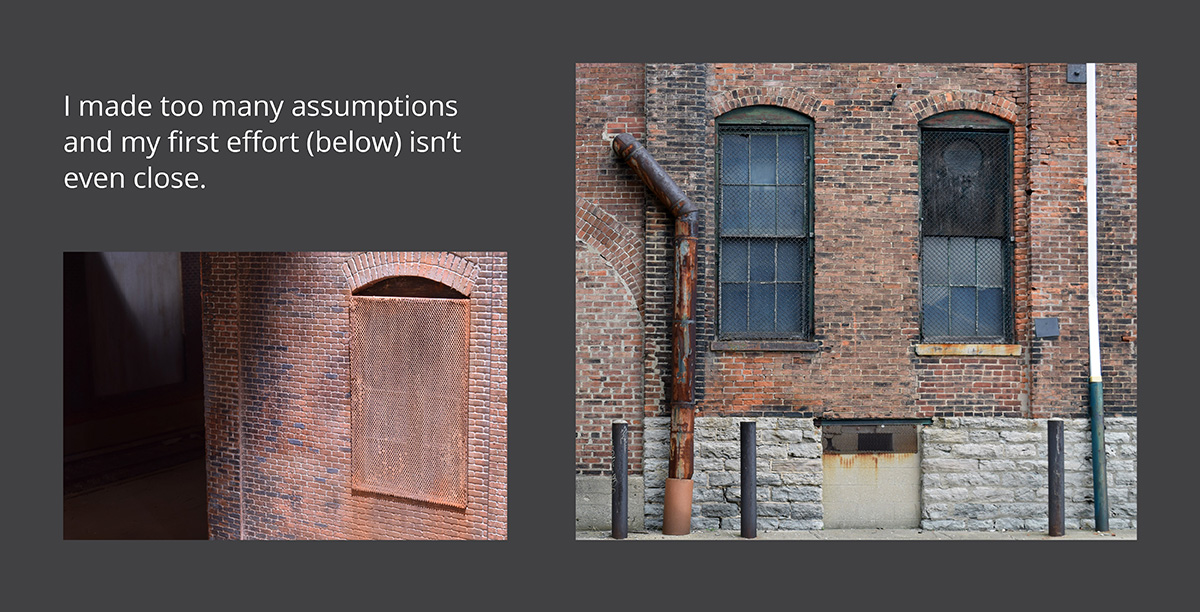

Modeling for me is about paying attention to the details. That’s something I didn’t do with the window screen for the Drill Company. Instead of reviewing my photos, I made things up in the belief that it was correct.

Prompted and encouraged by Matt’s comment on the last post, I discovered my mistake. The material choices in the first screen I built are grossly oversized. Compared to the actual screens they are clumsy looking. The discrepancy is so great that I made a new one that is closer to scale in appearance.

The real take-away here is how often I approach the work and let my own hubris lead the way. I’m focused on an outcome of some kind regardless of how I get there. I simply forge ahead and then worry about fixing any mistakes afterward. What if we paid more attention to how and why such mistakes happen in the first place? I could have easily checked my reference photos before hand. Why didn’t I, is a more useful question than how can I fix this?

Too often, I’m my own worst enemy.

Mike

A new frame of 0.033″ wire and some wedding veil fabric do the trick.

Lower storey factory windows needed to let the light in, along with all the good stuff as well, nicely done.

Thanks Glenn and welcome. -Mike

Looks perfect, for a few seconds I was wondering why you’d posted two photographs of your reference!

Thanks Mark. A warm welcome to you too.

-Mike

Very nicely done! The new screen is fantastic. As always, I’m impressed with your willingness to fix what you’re not completely happy with. Keep advocating this mindset!

Long ago, when asked, a friend told me that he built all his trestles with slightly undersized wood as it was more convincing than actual sizes in small (HOn3) scales. That advice stuck with me as very true for open structures and objects and I think your screen demonstrates this well, and that in 1:48 there is even greater opportunity for exploiting this to advantage.

Hi Dave,

There really isn’t a good reason for not redoing the detail. It didn’t take that much time and the results are far better to my eye. Paying closer attention to scale dimensions such as thickness and cross section is something I’m doing more of, as you’ll see in upcoming posts.

Mike

Are you going to pull out the pair of 4/4 windows and replace them with one 6/6? Or did I miss something in previous posts.

Just how far is this going to go? At what point are you drawing the line? It sounds like you’re being too hard on yourself. I agree your first effort didn’t look like the prototype, but then again it seems odd that the window behind the screen doesn’t match the window in your prototype photo.

Hi Galen,

This building has been expanded and modified many times over the years. There are sections with 4/4 windows and others with 6/6. There are sections with a single window in each bay and some with doubled. The single wall section of the model reflects the character of the building. To that end I was careful to maintain the number of brick courses and other key dimensions.

Mike

Vast improvement Mike. Over the years I have learned to throw out my pride and do it again if it needs it. That is easier in the long run than changing it later or thinking about what you dont like each time you look at a model. This way allows you to focus on how good that really does look and not “if only…” and “next time….”

I do agree with Galen though, you really are hard on yourself. But, it really looks nice and you can pat yourself on the back once in a while too.

Keep it up!! Steve