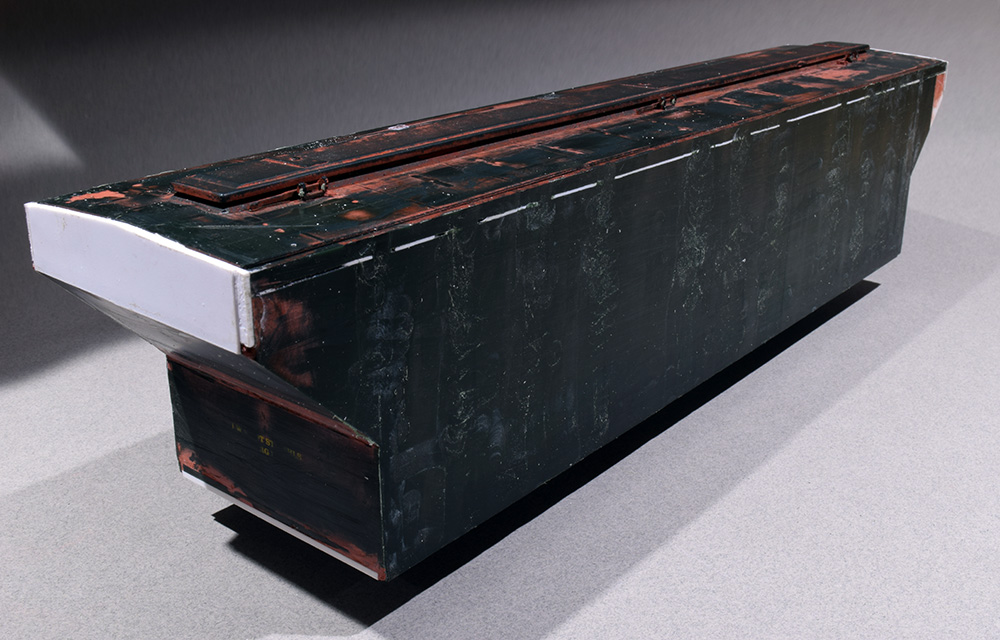

My reasoning centers on replacing the side sheets. These panels are 5/32” thick sheet steel on the actual car and I want to see that thin cross section where they overlap the slope sheets on each end of the model. These types of visual upgrades are the main reason for this project.

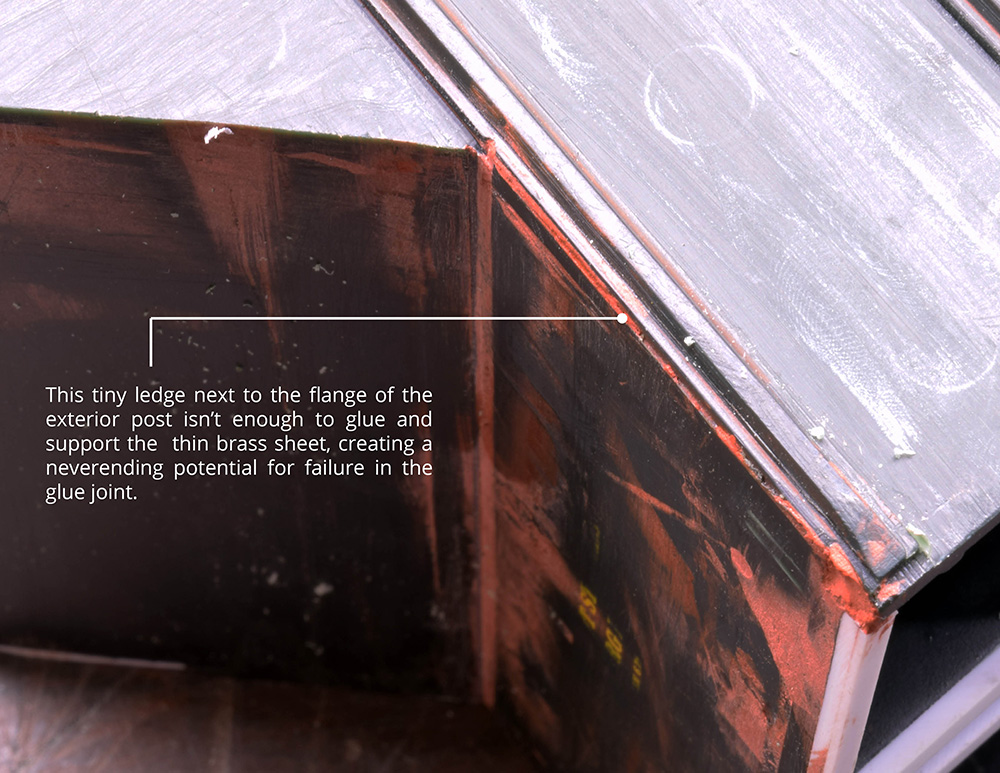

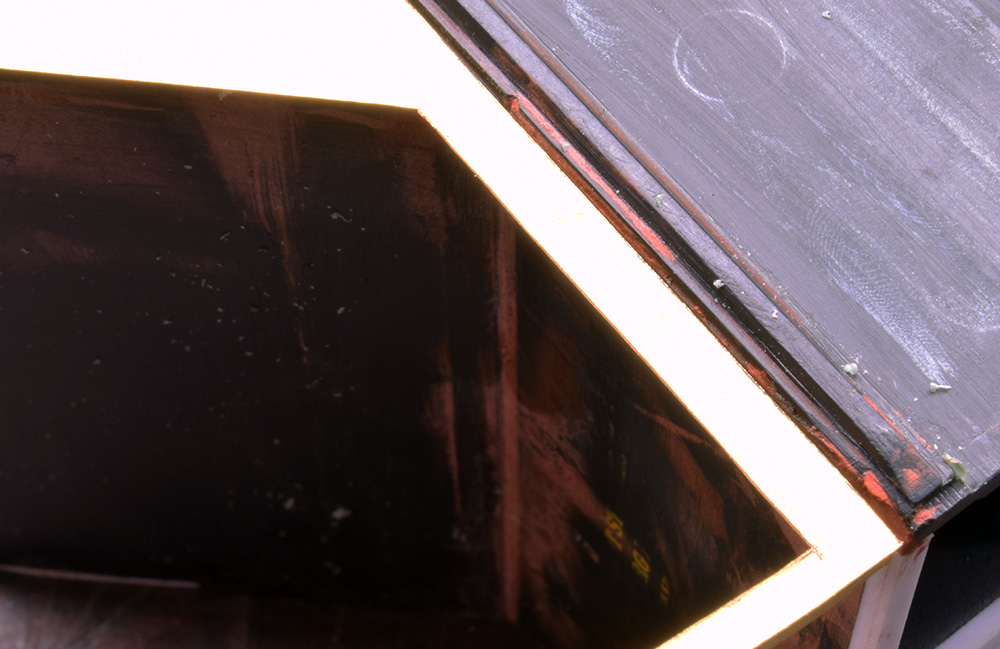

After removing the cast on overhang on each end there isn’t enough support next to the flange of the end post to attach the new panels along their length. This is going to be a problem because it’s all but impossible to edge glue material this thin (two photos below).

I’ve already made two attempts to apply new side sheets of 0.005” styrene and haven’t been happy with the results. In both cases I stripped the material and glue/CA residue off to start over. Clearly that approach isn’t working, so I stopped to evaluate what is going wrong.

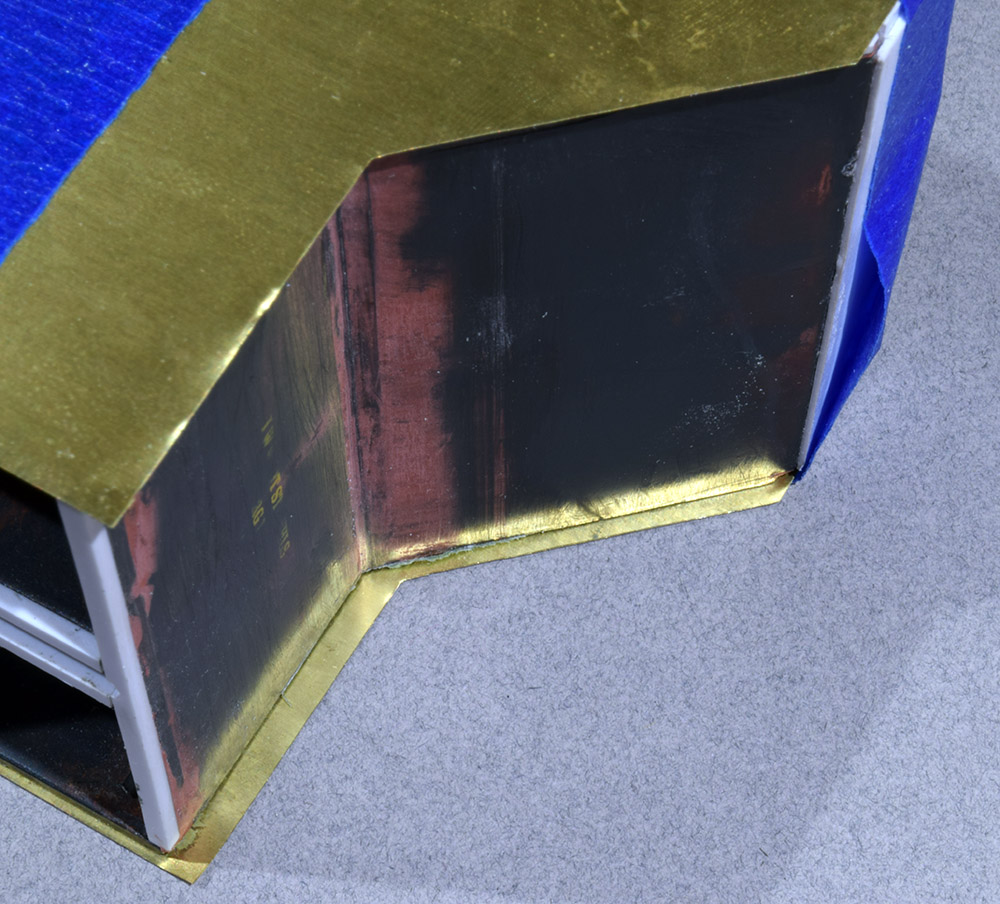

I need to use more than one piece to cover the sides and my initial thought was to minimize the number of joints in the material by using large pieces. I also thought that CA was a better choice over styrene cement to attach these wafer thin pieces. With CA, the main problem is positioning the sheets and getting an even amount of overhang on the end. A consistent overhang is critical to the appearance of the car, so a sloppy job simply won’t do. In addition, there are a number of connections for the end cages to consider. The cages will be brass and it makes sense to me that the side sheet in this area should also be brass, with an eye toward possibly making a soldered connection here. That idea is tempting, but likely impractical given the plastic shell underneath.

After a couple of days away from the work, I was playing around with some scraps of 0.005” brass sheet when I realized the side didn’t have to be of the same material across the length of the car. Since I planned on hiding the seams under one of the posts, I could use brass where needed and fill in with styrene sheet for the rest. Using smaller pieces for the end sheets let me fine-tune the fit where it matters, and position the seam on the opposite end wherever I want. (I’m slow but I get there eventually.)

Typically, my next move would be to attach everything to the shell but I haven’t done that yet. At this point a number of things and their assembly sequence need to be considered. The end cages are straightforward but there is work to be done on each end of the car before they go in place. Fitting the brake gear on the B end for example, needs to happen while there is easy access to the area. Also, given my gift for clumsiness, I don’t want a lot of delicate detail on the car until I absolutely have to attach it. I’m still working out the how, what and when order of it all in my head.

It feels like a hurdle is being conquered. I’m getting more comfortable with the level of work involved. There’s a growing sense of commitment to do things to a high standard that feels good and a satisfaction that is hard won in doing so. This is enjoyable work.

Regards,

Mike

I have been taking an online course in project management recently, mostly to formalise my existing knowledge and practice, but also the refine and improve it. Although I don’t like to bring work into my hobby, one thing has struck me as a parallel to what you are saying here, Mike.

Make sure the parties involved are clear on the objectives of the project.

And keep making sure.

Hi Simon,

Yes, I think we’re coming at the same idea from different directions. -Mike