When I get stuck or bored with a project I will set it aside and do something else. I tend to come back to these projects at odd times and for no reason other than it feels right. I hadn’t worked on this box car for a long time, even though it only needed a few more details to finish the work.

What is actually going on is a process of getting my head out of the way of doing the work. I must be ADD or something because I can go sour on a project in a heartbeat and that’s what happened here. I needed to recharge mentally before I screwed things up, which I am an expert at doing.

The only missing details were the lowered brake wheel, stirrup steps, uncoupling levers and air hoses. These are all somewhat fussy even in quarter-inch scale and that was the problem. You see, I have very bad work habits that I’ve nurtured over a lifetime. Habits that wage war against the kind of quality work I long to do, so I have to get my head in a good place before anything useful happens at the bench.

In this case, I decided to make each detail its own project, in the hope that I could stave off boredom or a sense of frustration from the amount of work ahead of me. The air hoses seemed simple enough, given that I haven’t been at the modeling bench for a long time.

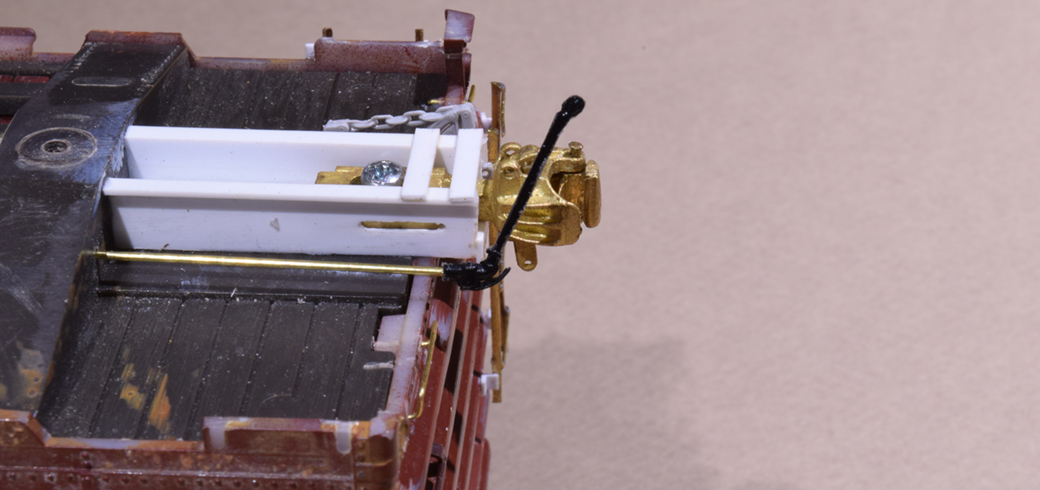

I prefer to use the excellent brass angle cocks and glad hands from Prototcraft but I was out of stock, so I found some plastic air hoses that I decided would have to do. The problem was the train line extension was too short and would not only look goofy but make mounting them difficult. (Did I mention simple?) I only had the two that I needed so there was no room for a mistake. (Getting simpler by the minute.)

I decided to cut off the alleged train line and mount the angle cock and hose on a piece of brass wire that I could insert into the truck bolster. This involved drilling a hole on the end of the angle cock. Woody Allen is often quoted as saying that 99 percent of success is just showing up and I’m convinced that 99 percent of successful modeling is being willing to try something difficult.

I won’t burden you with the sundry details surrounding the drill bit sizes or the procedure involved; you’re all accomplished modelers who can figure that out. I did manage to bungle up one of the holes but was able to salvage the part and use it. This is really a post about trying.

For all the rhetoric on this blog about craftsmanship and skill, I’m painfully aware of my shortcomings as a model builder. I’m painfully aware of how much time I’ve wasted over the years and how far removed my actual skill level is from where I’d like it to be. As you can see from the photos, I have a long road to travel and precious little time left for the journey. But, there is no other way to get there. I let myself be intimidated for years by certain materials and techniques and missed out on a lot of enjoyment as a result. Why?

Mostly because I was scared and had no faith in myself or my ability to learn. A craft like this provides a safe haven for such learning because mistakes are seldom, if ever fatal. So you mess up some plastic or bits of wire. Cut some more and do it over. But, if you aren’t even willing to try, then you’re denying yourself the opportunities that might become very enjoyable given enough time. If I come across like a crabby old man, it’s because A) I am a crabby old man and B) I’m profoundly saddened over where things seem to be going. I can’t do anything about the second one but the crabby old man can spend more time at the bench.

Regards,

Mike

I’m glad it’s not just me!

Simon