Recently I was watching a video from Stephen’s Custom Models where he used a CNC router to cut parts from brass sheet. Given the current work on the bench, my mind went into a predictable foaming frenzy and I thought: “I have got to get me one of those!” Until that is, I took a closer look at the reality.

This is not new or as spur of the moment as I suggest above. I’ve looked extensively at the tech involved and the investment of both time and money required to simply do some basic operations and the answer for now is, no thanks.

I’m aware that many of you may be thinking: Oh hell yes Mike, go for it. You won’t be sorry.

That might be true but I’m not naturally computer savvy and there is more than just buying a new machine and turning it on. I would be starting from zero with learning to design in CAD software and to program the router with G code to run the design. Looking at some of the CAD programs involved quickly produces a hazy fog over my eyes and mind. Sure it would be nice to produce parts like freight car sides, that are identical and dead on accurate but, there are low tech methods that get the job done as this video from Chris at Clickspring demonstrates. For now, the new tech doesn’t make sense for my purposes. I model for my own enjoyment and relaxation. I’m not interested in doing production work or offering stuff to others. At my current stage in life it seems wiser to make the fullest use of the equipment on hand before filling up the shop with more.

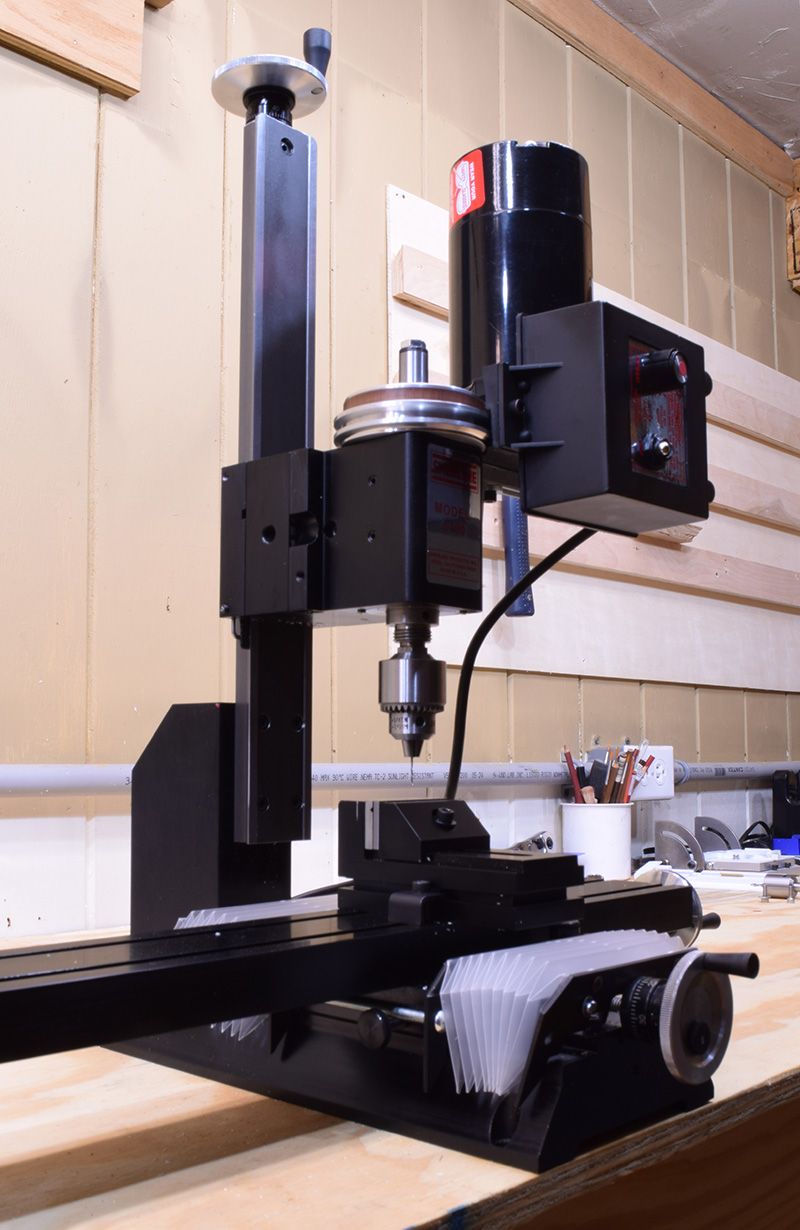

This Sherline mill was a declaration of my intent to take modeling very seriously. It’s an expensive machine that I’ve considered for a number of years while debating whether or not it was a wise expenditure. I’m glad I waited until I grew into the work and was ready for the advancements it made possible. I could upgrade the machine to a CNC operation but, the process and software involved leaves me feeling brain dead. It does beg the question: is it the machine or the willingness to push myself that truly makes the difference? I suspect it’s a bit of both.

Drilling this series of No. 78 holes for rivets would be far more difficult without the precision of the mill.

It’s The Chicken And The Egg

There’s a myth common to most creative pursuits that the tools and gadgets are what makes all the difference.

Well, maybe.

Good tools can certainly enhance the quality of a work but will never be a replacement for your own imagination, curiosity and willingness to just try stuff. In my experience, advanced machinery allows you to waste material quickly, until you learn what the machine can and can’t do. Learning to respect various materials for what they are is another aspect of getting the most from the craft. I’m finally on the verge of understanding brass as the metal that it is instead of thinking of it like really stiff and hard to work plastic. It may sound ridiculous but it makes a difference in the outcomes and my enjoyment of the work.

The more you work with a tool or material, the better your understanding becomes. You internalize a knowledge base that only increases with time and experience. That truth applies equally to digital tech as analog. I truly enjoy getting my hands on the material and working it into shape. My mindset has grown from fearing mistakes to embracing them as the learning opportunities they are. I’m learning to love the process of modeling and the ways the mind and hands inform and work with each other.

In closing modeling is what you make of it. I take a deliberate and considered approach because I want to and because I enjoy it. I can produce the outcomes and quality I want with the tools I currently have. In time my aspirations will grow and so will the shop. I may plunge into new technology or not but that isn’t really the question. New tech or old, it’s all nothing more than a tool waiting for your input. What do I want from this craft and who do I want to become as a modeler are the questions that truly drive the choices for now and the future. Thanks for reading.

Regards,

Mike

“Only buy a tool when you know why you need it, and then learn how to use it.” A late friend gave me that advice, and it’s as relevant now as it was then!

Afterwards, you will wonder how you ever got along without it, but if you buy a tool before you understand why you need it, it ends up becoming and expensive and lumpy item taking up space!

This applies to hand tools as well as machine tools.

That is solid advice Simon. I find myself becoming more discerning with tool purchases these days. My airbrush sits in a drawer more than it’s used. It’s good to have it but I find I have to relearn how to use it each time I pull it out. -Mike