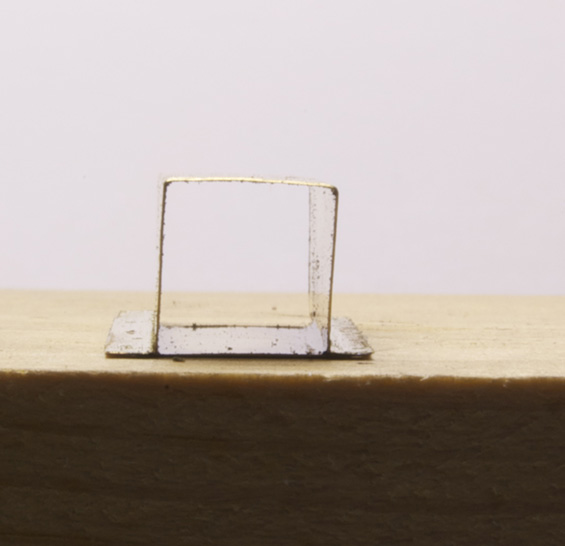

What’s wrong here?

They are several things but the most glaring to me is the out-of-square nature of this draft sill. (Draft sill is the term used in my 1966 Car and Locomotive Cyclopedia to define the underframe structure that houses the coupler, the coupler yoke and the draft gear. I’ve erroneously called it a center sill extension and hobbyists refer to it as a coupler pocket.)

Originally I made these from 0.005″ brass sheet using good working methods, such as measuring off of a scale rule with calipers, rather than using the rule itself for layout and scribing each line from a common reference point on the sheet, all in an effort to reduce compounded errors. Still, the part didn’t turn out accurately and I didn’t discover this until later.

The Analysis

On one of the parts I noted one side was longer than the other as a result of a sloppy fold. I looked closer to see if the fold was off from my layout line and it didn’t appear to be, which lead me to consider the accuracy of the layout itself. I double checked and all seemed good, so chalk it up to sloppy workmanship on my part.

Comparing the part to my reference photos, I felt that 0.005″ stock, while dimensionally correct, lacked the visual heft of these castings, so I remade them in 0.010″ brass. Better I think, yet my first attempts in the thicker material also came out skewed. In fact they were worse than the originals.

I attribute this to my working methods with the folds. In both cases I scribed lines on the inside surfaces to locate the fold and then scored them more deeply to encourage the material to bend where I wanted, similar to doing an etch. I do not have a proper bending brake, so I’m clamping the stock under a thick piece of steel bar and folding by hand using a makeshift tool. Clearly, this isn’t optimal, but it’s serviceable for these initial forays into the world of metal work. The pieces I’m creating are small and quite simple in nature and handwork has proven adequate for now. At this point I don’t know whether the investment in a small metal brake is justifiable, given the amount of work I foresee doing. Time will tell and I’m not in a rush.

Three separate attempts produced the two parts I need and beyond fabricating the pieces, my objective in this work is to build a solid foundation of basic skills and an understanding of the working qualities of brass. And, despite the suggestion by some that having to remake parts is frustrating, at this point for me it isn’t because I have managed to keep my expectations in check and simply focus on the work.

Thus far this has been gratifying on many levels. I’m discovering a joy in working with brass, as it opens possibilities beyond styrene. There is also joy in stretching beyond preconceived notions of what I thought I was capable of doing. These are among the benefits a hobby can provide and at the end of a work session, I walk away with a great feeling of satisfaction.

Regards,

Mike

Mike, folds are amongst the most difficult things to get right when metalworking. Don’t beat yourself up. For thin stuff like this job, I would put the scribed lines in a smooth jawed vice so that they sit on the jaw line, then slide a steel rule under the bit I want to fold and bring that over. The first can be taken almost to a right angle, the second not so far of course, but enough to get the bend point. Then finish with a pair of smooth pliers and a hard old thumb.

Only when the folds are made should you trim the lengths of the “legs” to ensure it sits square. Always start with more than you need on the principal of it’s easy to remove, not to add.

Hi Martin,

I did something similar to your suggestion for the final two folds on this piece. Because of its shape I quickly learned there was a definite sequence to making the four folds required.

I laid out the piece and trimmed to the final size before folding without too many problems beyond those outlined, which I attribute to inexperience more than anything.

With regard to “beating myself up”, I’m simply being blunt in my comments about the work and my experiences around it. Too often, people gloss over their difficulties with a procedure like this, leading others to believe everything just falls together on its own. I’m simply sharing what is actually involved in making these components as a beginning student in a new medium, in this case metal.

Regards,

Mike

Without the difficulties, where is the sense of satisfaction that comes with overcoming them?

Simon

Indeed.

Regards,

Mike