Making The Choice Between Handlaid and Commercial Track

As the author of a book on handlaying track, the following statement may sound strange.

The Gorilla In The Room

Let’s address the gorilla in the room from the outset: handlaying track with the amount of detail shown here is labor intensive, time consuming and expensive. The quantity of tie plates, joint bars and other details adds up very fast and these items aren’t cheap. Placing four spikes per tie is a herculean task with many feet of track to do. It isn’t for the faint of heart or those who lack the patience and persistence to see the job through.

Reasons Against Handlaying Track

If you want to get track down quickly and move on to other things or have a large area to cover, then without a doubt, commercial track and turnouts are the better option for you. With care in assembly and attention to painting and weathering, ready-to-lay track can look very good and perform well.

Handlaying track is a time consuming activity that requires patience and persistence. You’ll need to purchase either precut tie stock or cut your own. Of course you have to color the ties and glue them down. Working with small tools like needle-nosed pliers and tiny spikes can be frustrating. Your hands get tired and your vision may not tolerate working up close. It’s easy to introduce kinks in the rail when placing spikes and you only have to spill a container of them once to understand how irritating that is.

Placing individual tie plates is also frustrating as they often fall between the ties until you secure them with a spike or weight the rails down to hold everything in place as you spike. With regards to spikes, placing them every fifth or sixth tie may be functional and not noticed in a smaller scale but their absence is very noticeable in quarter-inch scale and that goes for the lack of tie plates as well. Spiking track is quite tedious over a long time. If you don’t have the tolerance for repetitive work, you’ll find it maddening. If you wait to place joint bars after spiking, you’ll have to remove and reset any spikes at each location because they will be in the way unless you planned ahead and left them out. With that said, why would you choose to handlay track?

Done with care, a combination of flex track and scratch built turnouts combines the strengths of both forms. This is what I did on my last HO layout using P87 track and wheel standards.

Choosing To Handlay.

The reasons are many. In addition to the appearance, handlaid track offers near total design freedom. You can build turnouts and curves with a seamless flowing line that mimics the prototype for smoothness and alignment. You can also achieve flowing lines with commercial track but, it takes time and care to do it right just like anything else.

With handlaid track you aren’t limited to the rigid, hard to modify geometry built into commercial turnouts. Furthermore, you aren’t limited to just two or three choices of frog numbers. A disadvantage with commercial turnouts is their generic appearance, especially around the points. The throw bar (the proper term is head rod) is designed and built for mechanical reliability over appearance. Again, the oversized appearance can be minimized with paint but it doesn’t match what’s possible with components that are in scale with the rest of the details.

These quarter-inch scale brass castings come in two pieces that you trim to size and insulate with a slip of paper. They reflect the prototype’s appearance and function beautifully. An N scale ground throw completes the image.

The old saying goes that nothing looks like wood better than wood. If you want track that is well maintained or decrepit, wood ties are easy to stain and weather to the degree of your choice. The plastic ties of commercial track can be painted as well and done with skill and a discerning eye can look quite good. Once again, getting good results takes practice and time.

Handlaying provides an opportunity for truly bespoke track work. You can replicate the nature, texture and appearance of full-size track to an astounding degree if you are willing to make the effort. For example, secondary track can be a hodge-podge of rail sizes and lengths, a visual image you can reproduce easily by scratchbuilding. Mixing different rail sizes along a single length of flex track is harder to do. It’s not impossible but entails a fair amount of work.

Wood ties can be weathered to any degree from brand new to rotting into dirt.

Of course there is the personal satisfaction of setting yourself a task and meeting the challenge. I can speak from experience that few things are as satisfying as watching a locomotive glide through a hand built turnout for the first time.

Moving Beyond Pros And Cons.

All of these points have been offered many times and are well known. In the end, it’s a choice you make based on your needs, your available time and budget. So what else is there to say?

What about a consistent quality in your modeling?

Too often one element on a layout looks out of synch with the others, drawing more attention than it should. Track often falls into this trap by sticking out like a sore thumb from the rest of the scene. Whether it’s the rigid geometry of commercial track or a lack of weathering, or a lack of understanding of full-sized track, model track often falls short of being all it could be.

The phrase “track is a model too” has been around for a while now. In fact we can treat anything as a subject worthy of study in its own right. I don’t know if it’s because of the quantity of track involved or simply a historic bias left over from the toy train roots of the hobby but we often fail to see the contribution that finely crafted track adds to the overall impact of our modeling. Further, with the quality many of us now expect from our rolling stock, scenery and structures, there is little excuse in settling for model track that has changed little over the last half century.

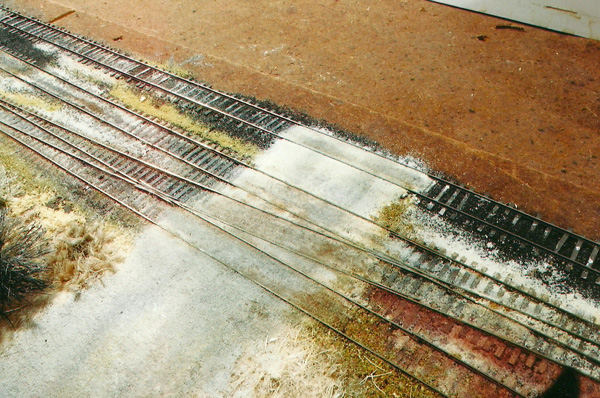

Track should have a consistent appearance that blends with the surroundings to enhance the entire scene.

What’s In It For You?

With the pace of technology and its growing impact on the craft, model railroading is becoming less hands-on in nature. The increasing emphasis on operations, modeling jobs and “work” brings even more abstraction. We’ve built an air of mystery around the idea of handlaying model track that positions it as some kind of black art reserved only for master craftsmen. The reality is that like any other skill, it will be hard at first and get easier with practice and experience.

However learning such skills is not beyond anyone and I encourage modelers to try their hand with a simple test section, just for the experience. You may like it; you may never want to do it again. Either way you will know yourself better.

Handlaying your track puts you in touch with the work in a tangible way. Progress is plain to see and the results are real. Pride of workmanship and modeling standards used is a very personal choice for each of us and, regardless of the materials employed, model track is a foundational part of any layout that deserves our care and attention.

Regards,

Mike

Well said.

Thank you Simon.

Mike

It was meant in both senses.