Commercial rolling stock in this scale is what it is. On the high end, there are stunning examples in resin and imported brass. These limited run items have few compromises and represent the state of the art. Some of the mass-market stuff is well done while other examples leave you wondering why they bothered to produce it.

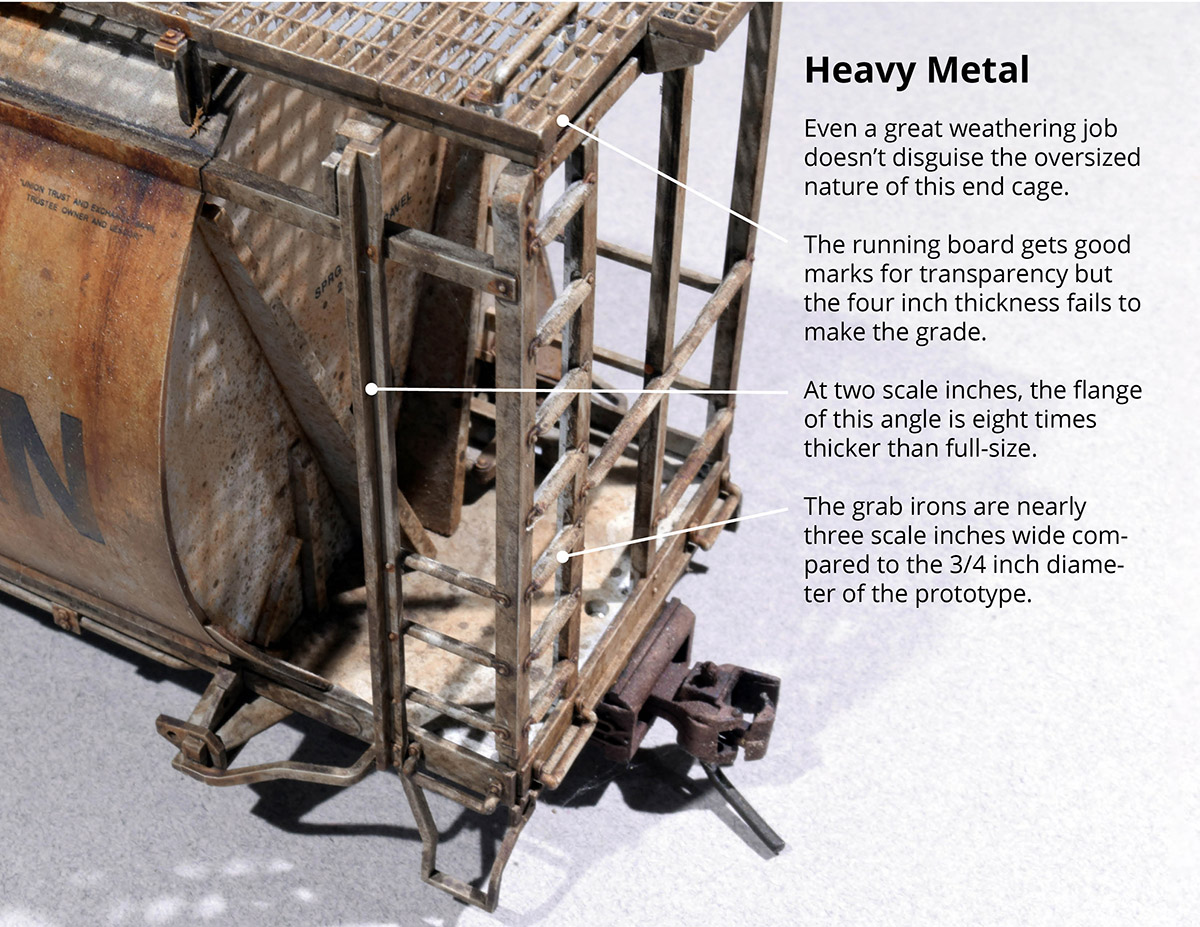

My most frustrating issue with mass-market rolling stock is how crude the detailing often is. With the 3-rail mentality driving these offerings, the details are often much heavier in form and cross-section than required. Admittedly, this can boil down to a matter of personal taste. Many people, regardless of their modeling scale, don’t care about such refinements as long as the wheels on the train go round and round. That’s all well and good, but I find an equal amount of joy in faithfully rendering every detail as close to scale as I can. If I can’t substantially improve the level of quality on a model, then I don’t see the point in going forward with the build.

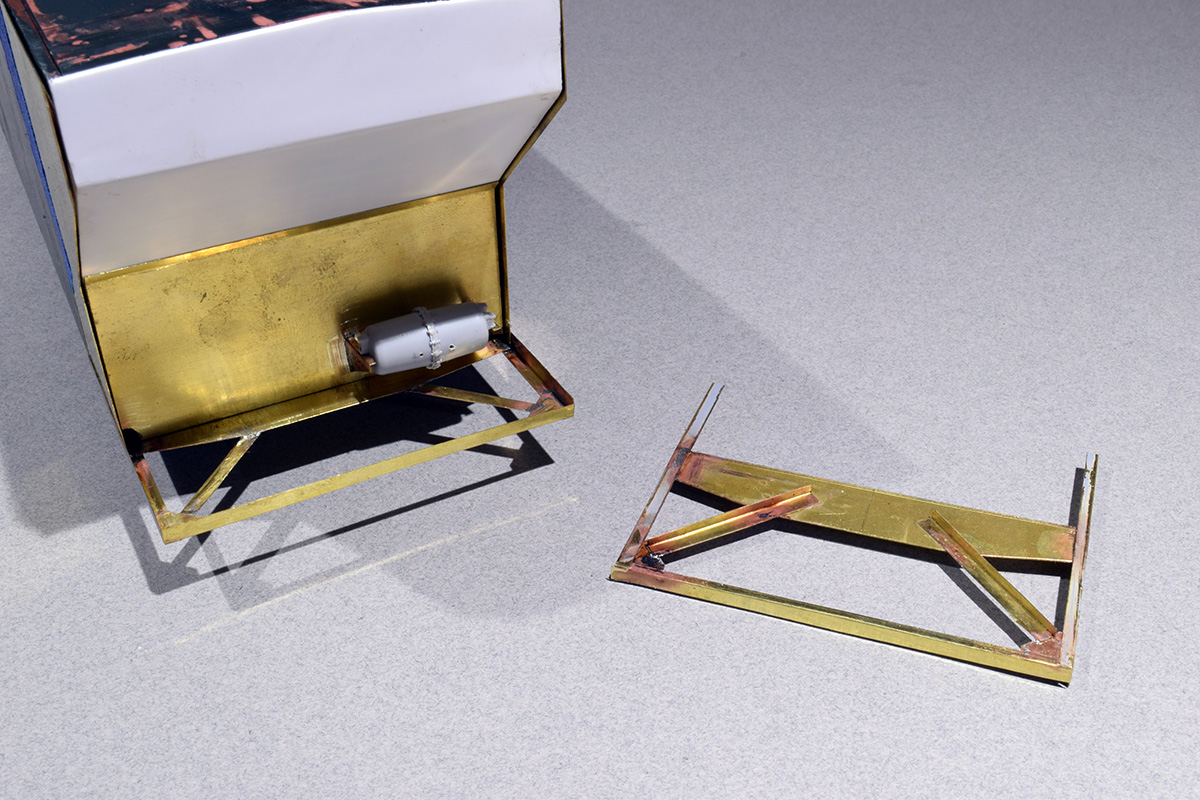

I’m using 0.005” thick brass and custom bending the angle stock to the sizes I need. With the hobby shops in my immediate area, it is getting harder if not impossible to find brass structural shapes in the smaller sizes I need. The last time I ordered some online they were stuffed into the box without thought or care. I managed to straighten them out but will not order from that vendor again.

Making my own structural stock isn’t as difficult as I once imagined. With practice, I’ve successfully bent angles as small as 3×4 scale inches using flat strips cut from a larger sheet. Developing this skill gives me a sense of modeling freedom, in that I can use components of the proper dimension instead of settling for the limited selection of sizes available. I also keep the project moving forward.

I made an assembly jig that holds everything in place for soldering. I spent a good amount of time and care building this jig, knowing full well the quality of the finished assembly depends on its precision. After an initial test fit on the car body, I made a few revisions before I was completely satisfied. I think the results speak well.

The assembly on the right is shown upside down, revealing the angular profile of the diagonal braces. Still to come is the draft gear and bolster, the rest of the brake gear, the corner posts and other structural members.

Regards,

Mike

Mike, I really enjoy following the progress of your work! I hope, you keep your Enthusiasmus.

Regards from Germany

Andy

Hi Andreas,

Thanks for commenting. I’m glad the work is enjoyable for you and I appreciate your encouragement.

Regards,

Mike