Fixing the issue involved breaking the glue joint along one side of the false floor, squaring up the assembly and re-gluing everything. For both cars this only took a half an hour or less and was worth the effort.

Another area I’m looking at is the hopper bays and gate openings. I have some variations between them on each car, due to my inaccurate layout with the template. Again, the discrepancies are minor and fixable, though it’s good to be aware of them at this early stage.

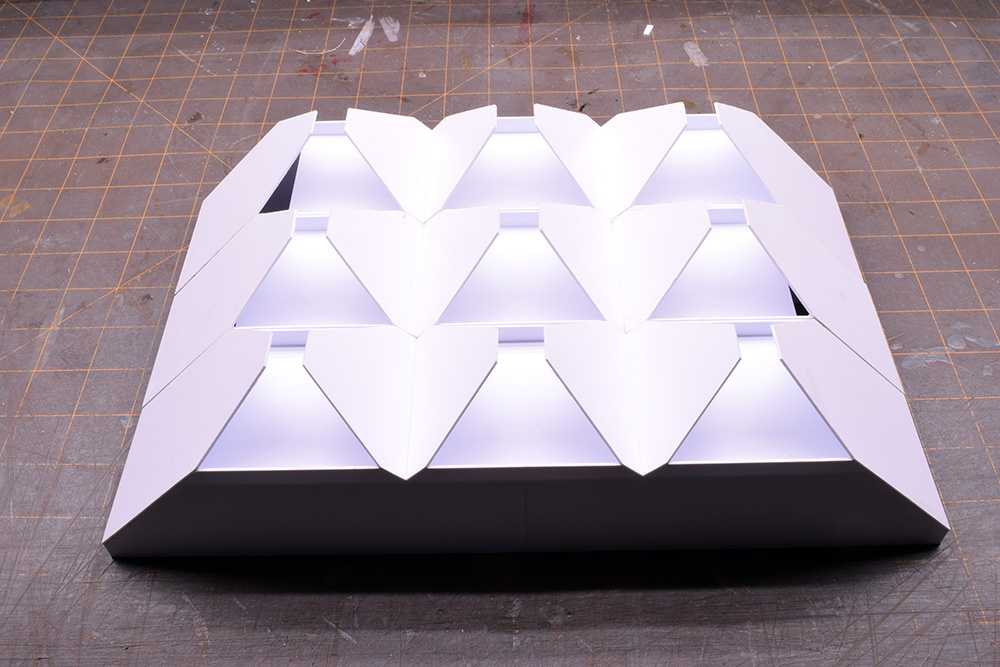

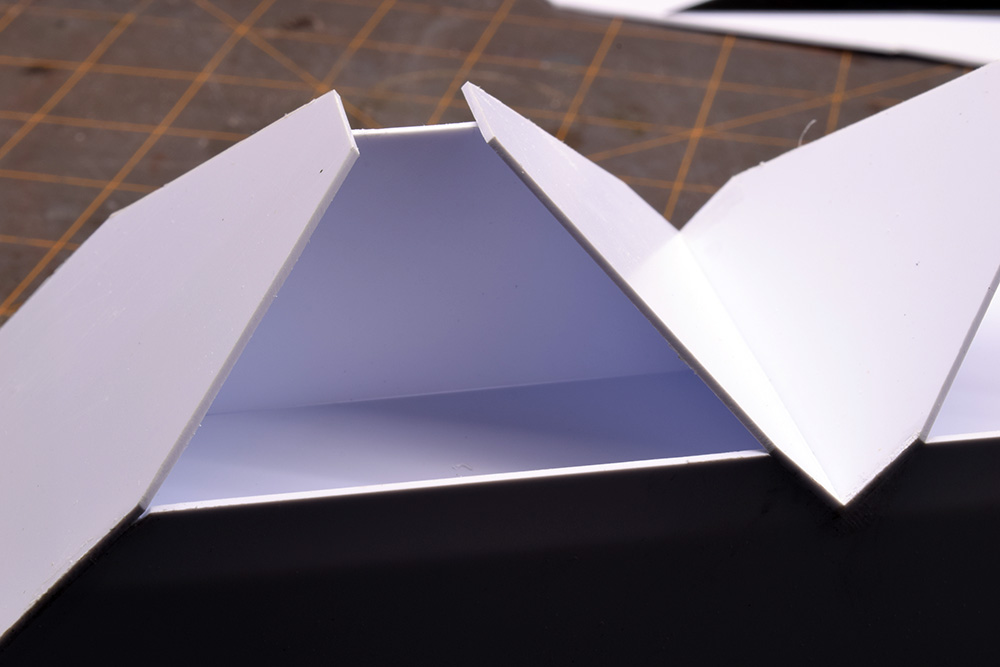

Before adding the side sheets for the bays, I’m installing internal bracing to strengthen them further. I plan to add a good amount of weight in each car and the extra bracing won’t hurt anything. This step should also take away some of the discrepancies between each bay on the cars.

A key objective for me is to have scale dimensions wherever possible on these models. The side and roof panels on these cars is 5/32” sheet steel and where you see the edge of a panel on the model I want to see a thin profile instead of grossly thick plastic. I will have to use several pieces of 0.005″ brass for each side and want the seams to land under an exterior post. Based on the plans, I’ll also look at the best way to detail the transition to the roof plane and the bottom of the side sheets. I have some careful planning to do when that stage arrives.

I’m pleased with how the build is going and feel a great satisfaction with the process so far. It’s relaxing in the sense that I feel no desire to rush through any phase, even though I have three models going at once. There are going to be snags and setbacks and I’ll deal with them as needed. If I hit a truly rough patch, I have other models I can pull out until I’m ready to move the cars forward again. For those following a project I realize it must be frustrating when I suddenly drop something and switch gears. However, this freedom of choice is the essence of the craft for me and I wouldn’t trade it for anything. In alternating between projects, I keep my enthusiasm for each one fresh, which helps me maintain a higher level of work than if I just plowed ahead with one until finished. This is how I keep things moving along. I’ve also discovered that things learned on one project translate easily to another and I’ve gotten several models unstuck this way. It works for me and maybe there’s something helpful for others too.

Mike

5-mil brass? That sounds awfully thick. Did you mean 5 thou?

Thank you. Yes. 0.005″ actually. I’ve corrected the text.

Mike

Breaking a project in several steps and allowing yourself to sit back then look at your work later is always a winning approach. Isn’t funny how we are ready to skip details when rushing a project because we perceive them as hurdles, only to came back a few days a later and find it trivial at best.

Matthieu,

I completely agree. I have done that to myself many times. Decide something is too big of a headache. Only to do it later and have it work out fine and easier than expected. The fresh start does help.

I have a project that has drug on for years that I just dug out trying to get back onto it. I find myself staring at it more than anything right now.

Mike, I am glad to see you have made it to mass production now. These will be worth the work I’m sure.