I use a lot of 0.005-inch brass sheet to provide the thin cross section of the sheet metal used on freight cars. Until now, I’ve purchased the prepackaged sheets from the hobby shop or craft store. With a decision to pursue brass work more fully, the limited size of this material is a problem.

A 4×10 or 4×12 inch sheet of brass is too short for a fifty-foot freight car in quarter-inch scale. Yes, you may piece together a car side and hide any joints, but there is always some highly visible structural component running the length of the car that requires a splice or joint of some kind. Poor work here can ruin an otherwise clean build.

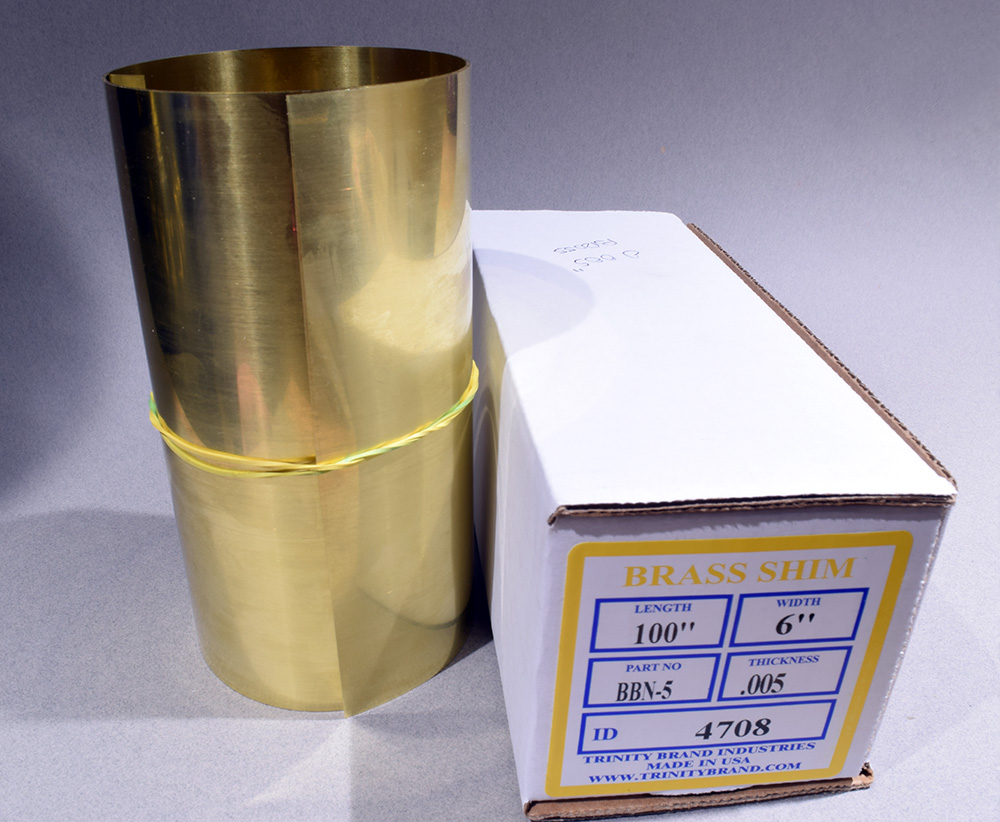

I’ve found myself in this situation more than once and it’s past time to do something about it. A quick online search revealed a wide range of brass stock in all manner of sizes and thickness. I settled on a 6” wide by 100” long roll of 0.005” thick shim brass from McMaster Carr (item: 9501K36). The link at the end of this post will take you directly to this product page of their website.

This roll of shim brass is less expensive than the small single sheets from the hobby shop or craft store.

McMaster Carr has stock that ranges from 0.001” up to 0.031” in thickness. They also carry 6”x25” or 8”x12” individual brass sheets, along with a variety of bar, rod and tube stock in different hardness and machining qualities.

If an 8’-4” long roll sounds like a lot, it is. (They also have four, five and ten-foot rolls.) I chose a roll, as it’s much less expensive than sheets for the same amount of material. I also like the ability to cut stock to any length a project requires.

Rolled material this thin will be springy with a tendency to curl but it’s nothing that can’t be overcome. I cut a practice piece and gently flexed it in the opposite direction of the curl and that helped to straighten it. Once any pieces are formed or soldered together, it’s fine. Using the bending brake, I made up a pair of 15” long zee sections that have a scale four-inch flange on each end with a scale seven-inch wide web in the middle. They came out as straight as any commercial product, so I’m very happy with my choice of this material. I paid $22.35 for the roll plus about nine dollars for tax and shipping costs. (Shipping will vary according to where you live.) At just over $31, it’s still a significant savings over an equivalent number of the single sheet packages aimed at hobbyists.

While none of this is news to more experienced modelers, I’m just starting to find my way with this aspect of scratch building. I freely admit I have a lot to learn about the basics of metalworking and how and where to find stuff. We all start somewhere and this is my starting place. I’m taking things one-step at a time to see what I can and can’t do and simply enjoying the process.

Everyone has their favorite materials and sources of supply. I looked at other vendors with similar price and selection but settled on McMaster Carr because I’ve seen the name referenced often in the modeling community. Their website is easy to navigate and my service experience was top-notch.

It’s important to know there are other resources beyond the stuff we typically use. While the smaller sheets still have a place in the shop, now that I know I can get the larger stock that I want, I plan to lay in a supply, start practicing my techniques and move a few stalled projects forward.

Regards,

Mike

Pretty soon you’ll be etching your own brass parts!

Thinking outside the box is a good thing.

Pretty soon you’ll be etching your own brass parts!

Unlikely Craig. I prefer to work with actual material and old school methods. I’ll leave the software modeling stuff like that and 3d printing to others. I also prefer to ignore the box whenever possible.

Mike