However, with each piece that turns out decently, that internal story breaks down and looses strength. I don’t have a lathe, milling machine, or fancy soldering equipment. I just have the usual set of basic hand tools that, so far, have been adequate for the work.

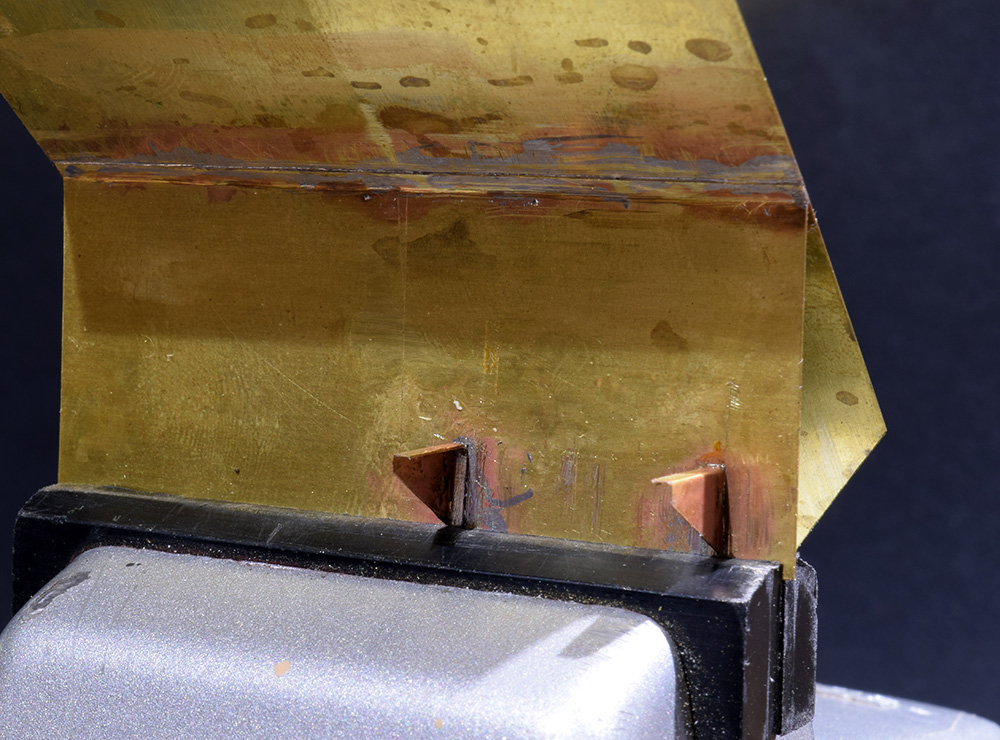

Brass is frustrating at times. Even with an assembly jig, for each piece you see on these car ends, I had to unsolder and reposition it two or more times before I was sure it was accurately placed. It’s slow work for certain but every success brings a satisfaction that’s hard to describe. It’s something you have to experience to truly understand.

Whatever model making entails for you, I hope you’ll stretch beyond your comfort zone and discover the gift of immense satisfaction waiting on the other side.

Mike

Your time with jigs is paying off Mike. Looks great. What do you cut your brass with?

Steve

Steve,

Since the 0.005″ brass is so thin, I use an X-acto knife and either cut all the way through or score it deeply enough to bend and break. It depends on the size and delicacy of the part. It’s probably not the best way but it works with the tools I have.

Mike

Using a saw would tear the brass. Using some form of snips/shears/scissors on .005” brass might work, but could easily distort the edges.

A heavy craft knife (in the UK what we call a Stanley knife), or a scrawker (aka Tamika plastic cutter) does the job perfectly well, and if it works for you, only change if you find an easier way of doing it!

Hi Simon,

I’ve used a utility knife such as you described and it works well. I might actually have one of those Tamiya scribers. I’ll have to dig it out and try it.

Mike

Jewellery supply houses sell iron “binding wire” which you can use to bind things in place. I have used it a lot for soldering jewellery, it’s dead useful. Also, you can twist it (with a dremel or similar) like a rope for heavier applications.