Warehouse Doors

I had two sessions at the workbench this week and it was good, productive time spent on the loading doors for the warehouse. I have ten to construct and I decided to treat each door as its own project. This approach reduces the stress from thinking I have an overwhelming task ahead of me. Completing each door gives a sense of accomplishment and, as they add up, that feeling only grows. I’m able to maintain my standards of craftsmanship more easily, because the volume of work in each session isn’t so burdensome that I get tired or bored with it.

I consider every project an opportunity to increase my skills by asking questions that help me understand where and how I might improve. The first door (below) had a number of spots and fingerprints from using too much solvent. In addition, some of the joints weren’t as tight and clean as I want. Realizing the conditions that lead to these flaws is the first step in eliminating them and, how will I know what those conditions are without a critical review that is as objective as I can be?

These doors are a prominent feature of the building and with the shallow depth of the scene, they are easy to examine up close, so they deserve extra attention. My current photos show them in a dilapidated state but the model is set in the 1960s therefore, I backed off on the texture effects, especially the wood grain. When you account for the reduced scale, wood grain isn’t as prominent as we tend to create. These doors would have been painted and well maintained in years past and the weathered textures I see today are wrong for that era. However, I do want some indication that they are wood, so a minimal amount of texture is appropriate. It’s a fine line to walk and though it isn’t apparent in the photo, I may have slipped up by imparting too much grain despite my awareness of this factor.

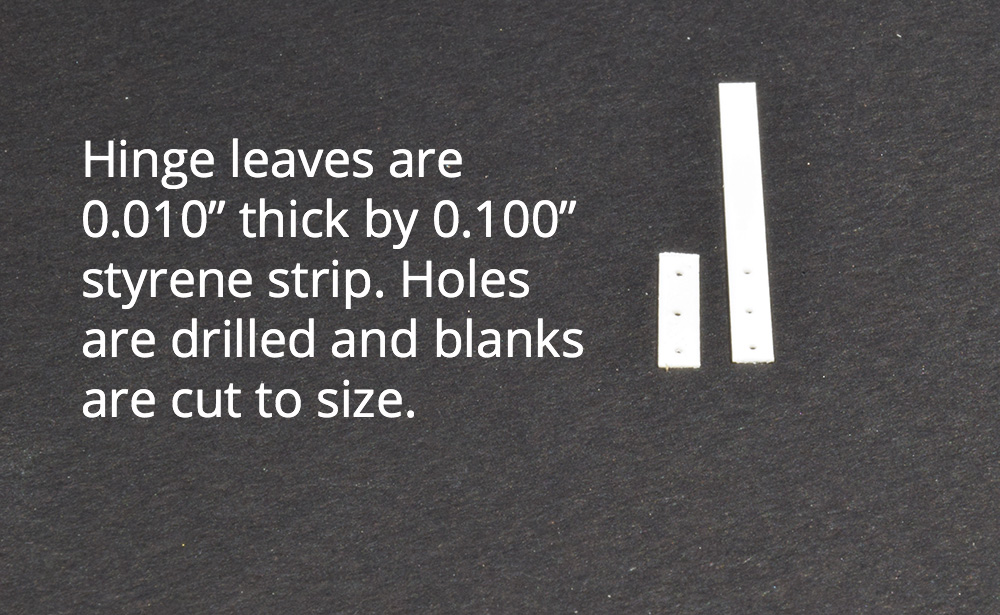

Another distinctive feature are the four large strap hinges on each door. I made these using production techniques that allowed me to fabricate multiple pieces at once. Each hinge leaf has three holes that need to be consistently placed. I set up a simple jig on my drill press that held a stack of eight pieces in position as I drilled the holes. I made the strips longer than required for easier handling and then cut them to length afterward. Each leaf was glued in place with a piece of 0.020” styrene rod for the hinge pin.

Once the hinges were positioned, I hand drilled through holes using a #76 bit for the Tichy 0.030” rivets. Many will look at this work, read the description and lament over how involved or fussy it all is. My response is that I don’t care. The work itself is enjoyable and produces the results I want. What more does one need?

Once the doors are completed, I will paint and weather them before installation on the model. I still have a lot of prep work to do on the building that involves rough handling, so I don’t want to load the shell up with delicate details that will be damaged in the process.

It’s good to have time at the bench again and to have clarity about the work. That’s a gift in any endeavor.

Regards,

Mike

“I have ten to construct and I decided to treat each door as its own project.”

Nice work, Mike, and it is interesting to see this point of view. Most recommend doing it as a batch job, yet in my experience more than two at a time induces boredom and disinterest. It is refreshing to see this advice/opinion expressed in public.

Simon