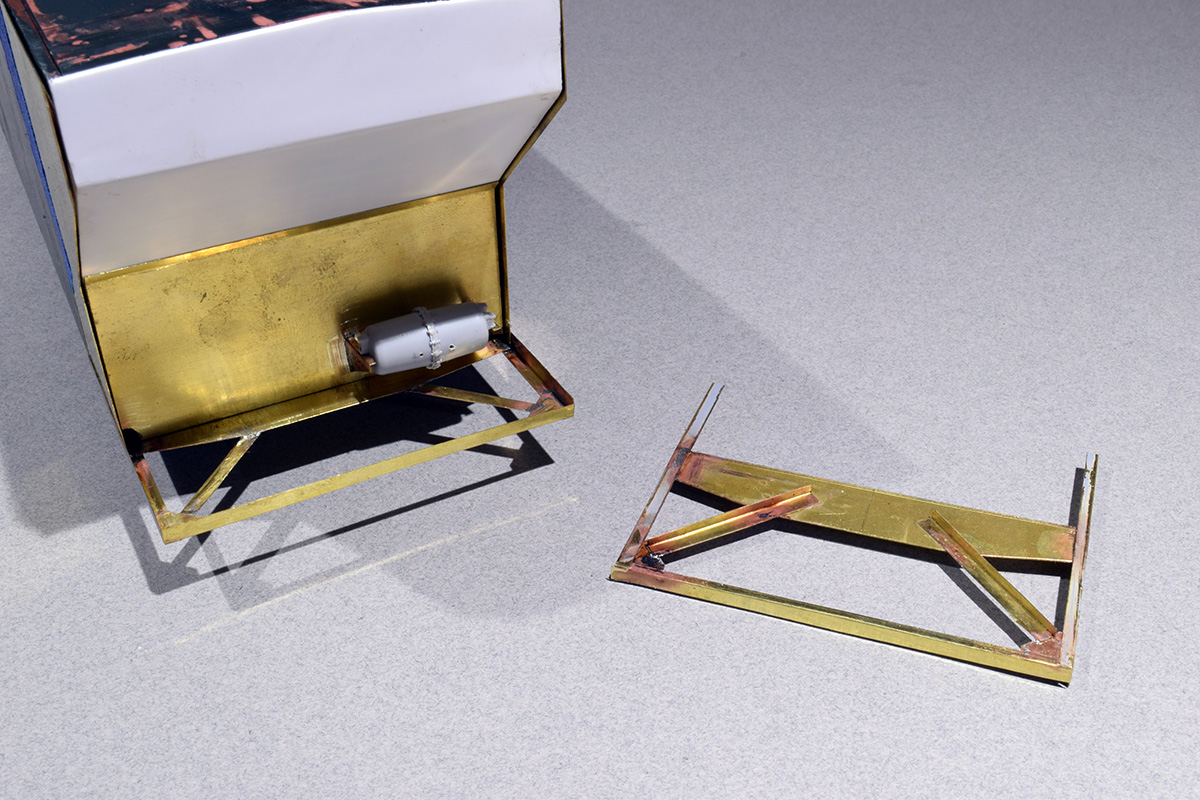

This would have worked just fine, although now that I have the ability to fabricate longer material, it felt lazy not to explore that option, in the hope I could eliminate unnecessary joints and mismatched dimensions. As seen in the image below, it was worth the extra effort to remake the assembly.

Since I’m using the same jig, the fit is the same as before and I was pleased with how everything aligned at the critical areas on each end of the car.

Before I secure the assembly to the car body, I’m adding the many smaller details like the stirrup steps, grab irons, roping staples and so on. It is much simpler to add these now while I can still fit everything in a jig for soldering and aligning the smaller parts.

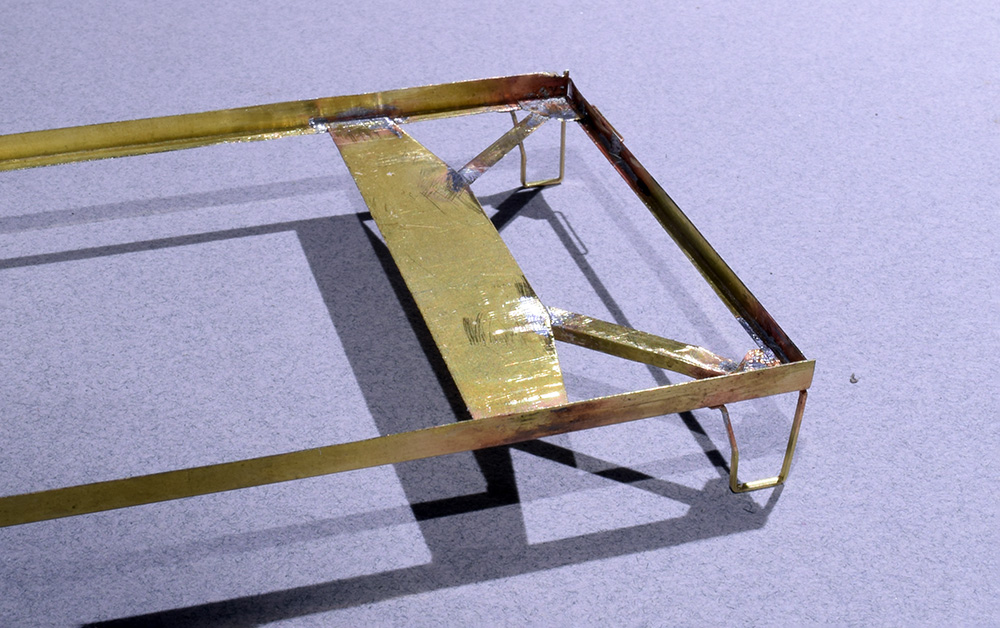

Things may look rough at this stage but I’m hoping the primer coat will even things out.

I’m glad I made this effort. The build will be neater and much improved.

Regards,

Mike

It won’t be long before you’re scratchbuilding complete rolling stock and locomotives….

That’s the plan Chris. -Mike