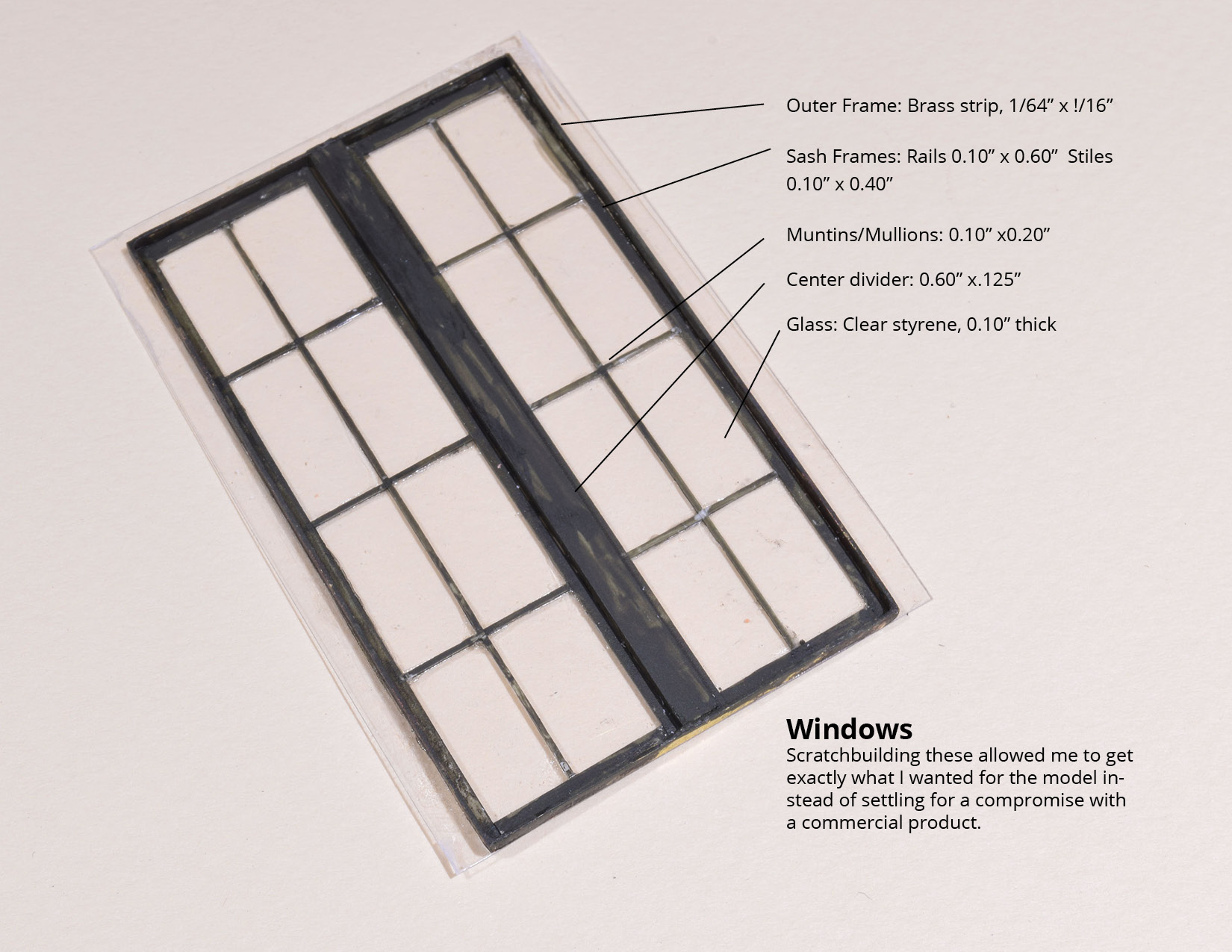

Windows

There’s progress on the Hoosier Drill Company. The windows are installed, the walls are painted and it’s nearly time for assembly and a roof. Once it’s in place on the cameo, I can fit the covered connector between the two buildings.

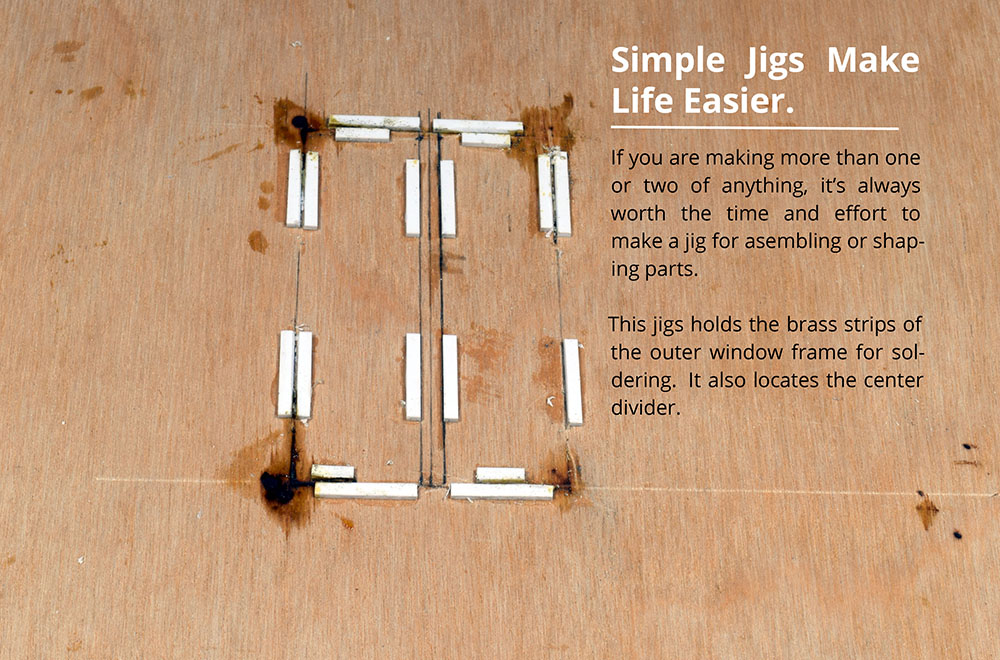

This is my second set of windows and they turned out well. I used a different technique that eliminated the gaps and poor fit of the first set. I also experimented with a brass framework around the perimeter instead of styrene strip. The 1/64 x 1/16 brass is stronger and helped stiffen the entire window. It was a simple matter to make a jig to hold these strips in place while I soldered the corners. It sounds tedious but is actually straightforward work thanks to the jig.

With the outer dimensions set, I build up each sash with styrene strip and clear styrene sheet. I pre-painted the various strips needed for sash and the mullions and muntins, and fit them in place using a drawing underneath the clear sheet. Once again this sounds more tedious than it actually was. Patience and a delicate touch got the job done.

I know some of you will suggest the many alternative methods I could have used. I’m well aware I could have modified a commercial product or used some form of mass production like resin casting. If I needed more than five or six, I would have made a master and cast them in resin. With only two windows it was simpler and faster to do it this way. Scratchbuilding the window frames also gave me exactly the pattern I wanted for this building. Duplicating the sash and proportions strengthens the character of the model in a way that a commercial product wouldn’t. The job was straightforward and I felt confident in tackling it. The regular work sessions are paying benefits.

Once this building is done, the cameo will be complete except for final detailing. The corner of 13th and North E is quickly becoming one of my favorite photography locations to capture what’s spotted at the warehouse (opening photo).

Regards,

Mike

Mike,

Using brass to form window frames – great idea. I enjoy working with brass and this concepts really rings home to me. I can see building or buying a ring roller in order to make arched topped window. I model in S and the selection of available windows leaves something to be desired. While I have done windows out of styrene, I have never been satisfied with the durability and/or appearance. Often times the muttons will warp because of the glue. Lastly, it’s often hard to get a good styrene to styrene joint especially when working with fine material. It’s easy to solder brass butt joints. With a little cleanup, the excess solder goes away.

Once again, thank you for your creativity and willingness to embrace new materials

Mike

Hi Michael,

The window situation is similar in quarter-inch scale. Durability isn’t the issue but a limited selection is. I’m glad I only needed a handful, otherwise I would have made a master and cast the rest in resin.

Mike